Have you heard of "ready-to-use, no post-processing required" liquid silicone? Against the backdrop of modern industry’s pursuit of efficiency and energy savings, a post-curing-free liquid silicone called the LSR 20 series is gaining favor among manufacturers for its exceptional process adaptability and stable performance.

5-Minute Curing: Dramatically Boosting Production Efficiency

The material consists of A and B components mixed in a 1:1 ratio. Under conditions of 130°C and 15MPa, it fully cures in just 5 minutes. By eliminating the traditional secondary vulcanization step, it saves time, reduces energy consumption and equipment investment, and is particularly suitable for high-volume, fast-paced production lines.

Outstanding Performance Metrics: Wide Applicability

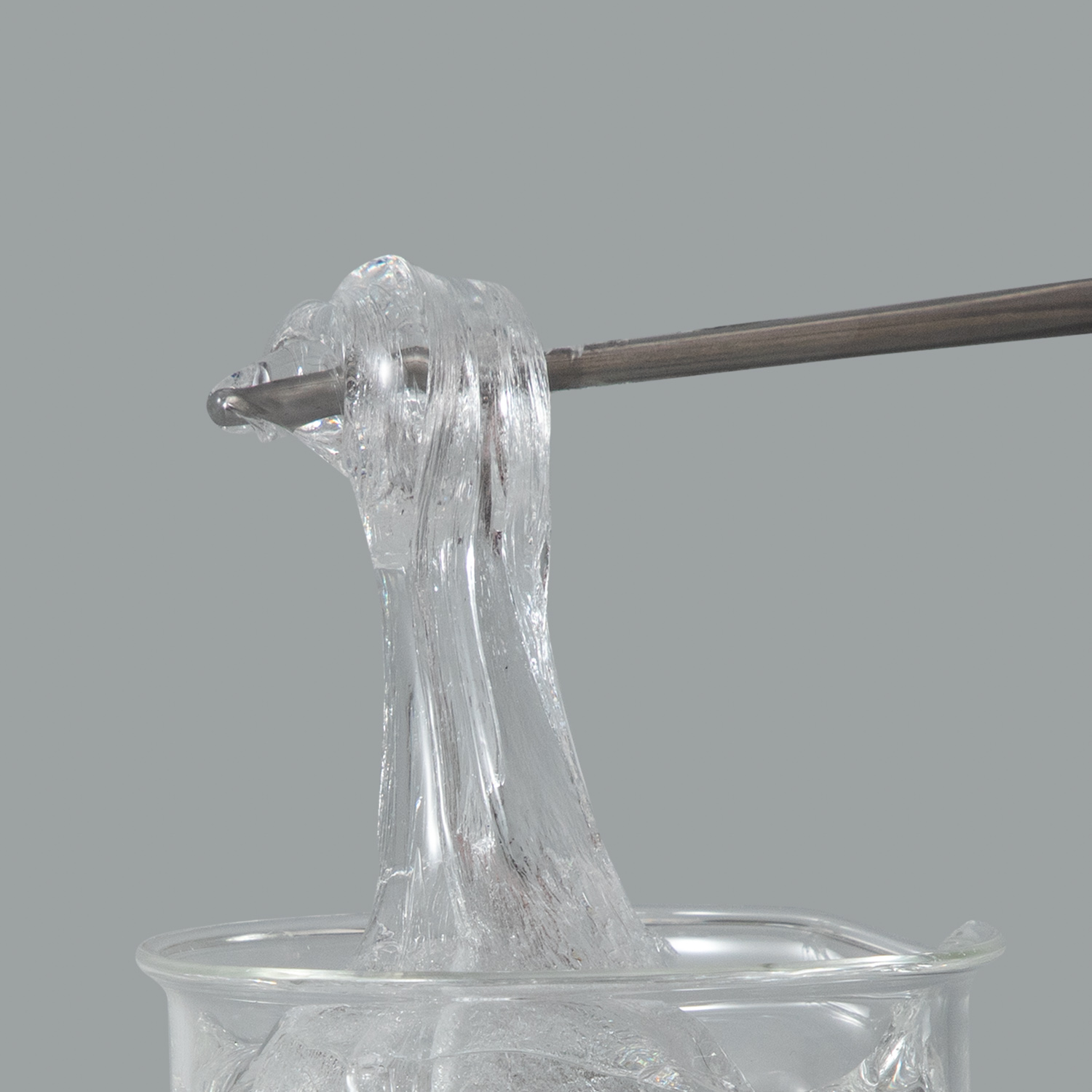

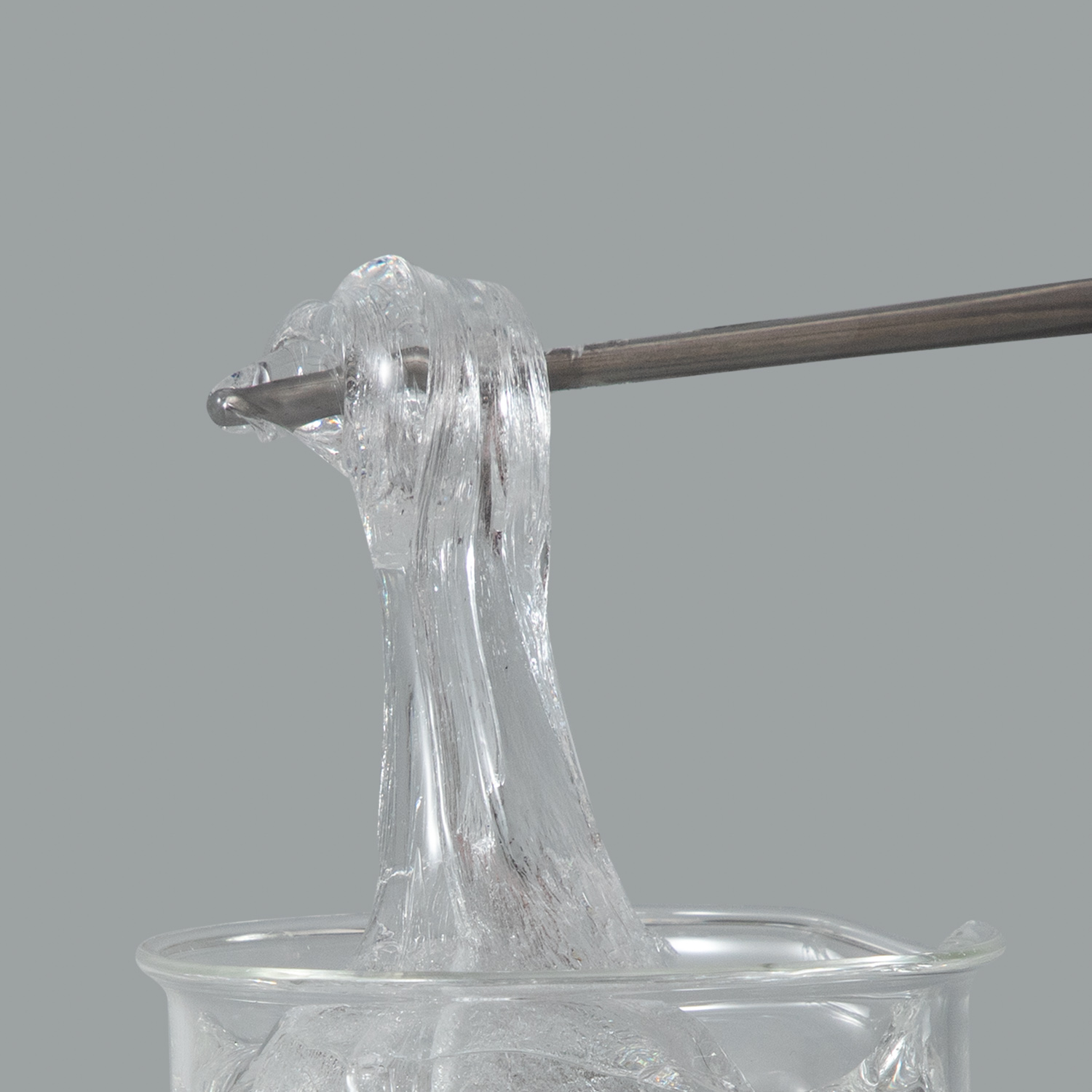

The series offers multiple hardness options (23A~68A), covering needs from soft to hard materials. Its tensile strength ranges from 6 to 10MPa, with a maximum tear strength of 35kN/m and an elongation rate maintained above 400%. These figures demonstrate that the material is both soft and tough, capable of withstanding long-term stretching and friction during use.

Low Volatility: More Eco-Friendly and Safer

The material’s VOC content is controlled between 0.3% and 0.35%, far below the industry average. Low volatility means fewer odors and a healthier usage environment, making it especially suitable for baby products with strict requirements for smell and safety.

Application Scenarios: Beyond Pacifiers and Baby Bottles

While initially developed for baby products, its excellent transparency, temperature resistance, and mechanical properties also make it suitable for medical devices, food packaging, electronic sealing, and other fields. Manufacturers can select different models based on actual needs to flexibly adapt to various products.

Usage Reminder: Avoid Catalyst Poisoning

The material uses a platinum catalyst system. During use, contact with substances containing sulfur, phosphorus, or tin must be avoided, as this may cause "poisoning" of the catalyst and affect curing results. Additionally, A and B components must come from the same batch and be fully stirred before use to ensure material uniformity.

Conclusion

With 5-minute curing, no post-processing, and balanced performance across multiple metrics, this liquid silicone not only improves production efficiency but also expands the application boundaries of silicone materials. It is a perfect combination of material innovation and manufacturing upgrading.