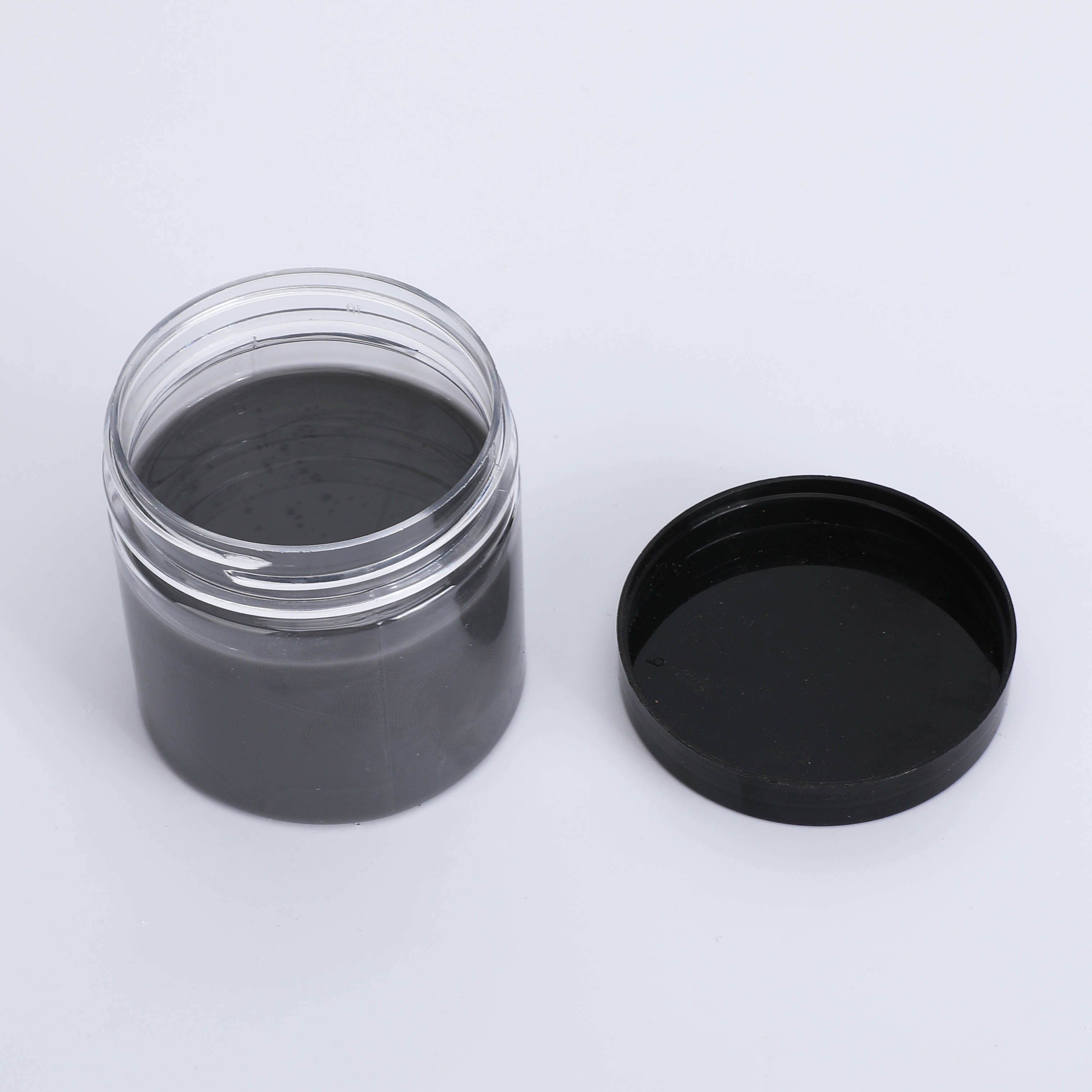

In the material market, there are not many products that can meet both printing and molding needs simultaneously. However, the GF(D,E)9730 and 9730-50 series ink-type liquid silicone rubbers achieve this with their comprehensive performance—whether it’s printing patterns or injection-molding parts, they can “handle the task with ease”.

First, let’s look at their performance in the printing field. As an ink matrix, they can flexibly adapt to three mainstream processes:

- For screen printing: After adjusting the viscosity, they can firmly adhere to the substrate surface, resulting in printed patterns with clear edges and no blurring.

- For pad printing: They can perfectly fit curved or rounded surfaces. For example, when printing logos on thermos cups—whether the cup is round or square—the pattern can be accurately aligned.

- For spraying: After dilution, they can evenly cover large-area substrates. For instance, when spraying an overall base color on silicone tablecloths, the coating has a consistent thickness and full color.

Moreover, regardless of the process, the cured coating is exceptionally durable—it resists stretching and tearing, and patterns are not easily worn during daily use. This solves the problem of “prints looking good but lacking durability”.

Next, let’s explore their advantages in the molding field. Designed with fluidity for injection molding, they can easily produce various silicone products:

- When making medical silicone catheters, they can fill the tiny channels of the catheters, resulting in smooth surfaces with no burrs after molding.

- When manufacturing food-grade silicone ice trays, their compliance with FDA standards ensures safety and non-toxicity. Additionally, the ice trays have good flexibility after molding, so ice cubes are not easily broken during demolding.

What’s more user-friendly is their low-temperature storage performance, which allows production to proceed unaffected by seasons. Even in winter, there’s no need to worry about the material solidifying—production can start at any time.

They are also thoughtfully designed in terms of usage details:

- Packaging is available in two specifications: 20KG/barrel and 200KG/barrel. Small manufacturers engaged in small-batch production can choose the 20KG option to avoid material waste; large manufacturers conducting mass production can opt for the 200KG option to reduce frequent restocking and improve efficiency.

- Both products have a uniform density of 1.11g/cm³. Whether for ink preparation or injection molding, this ensures consistent performance across every batch of products. There’s no need for frequent adjustments to process parameters, making production more stable and worry-free.