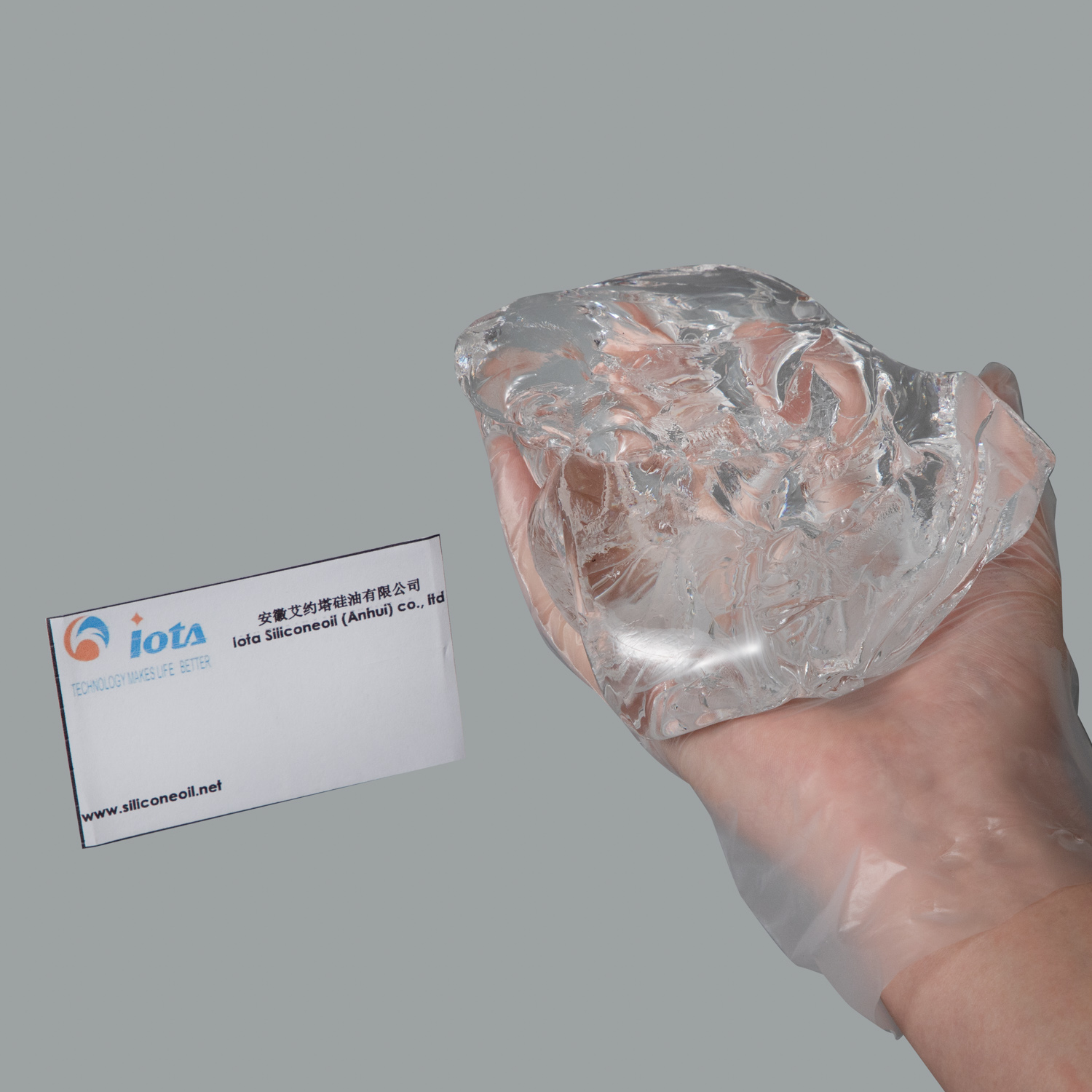

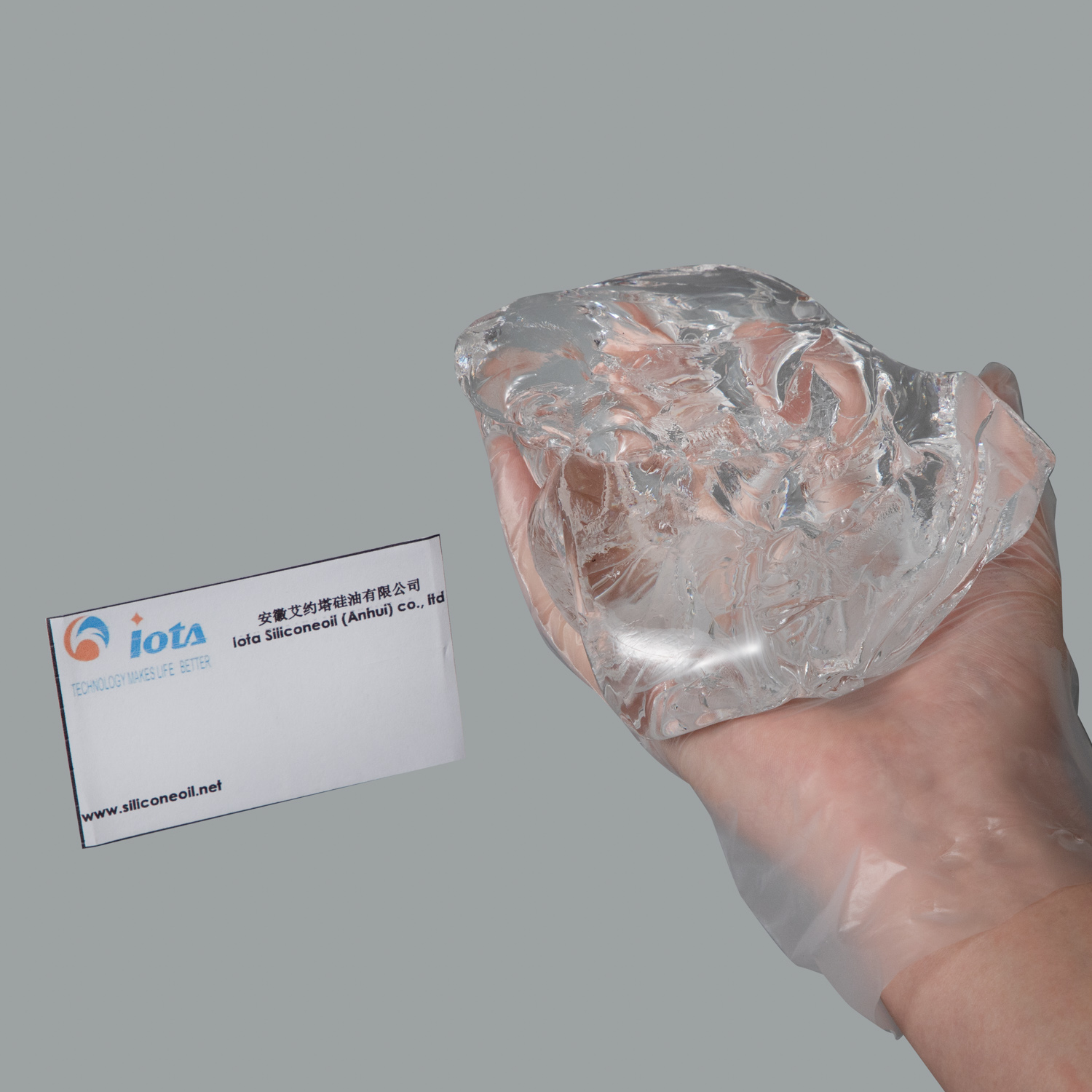

In special scenarios such as aerospace, nuclear industry, and low-temperature storage, materials are required to not only withstand extreme temperatures but also resist radiation, corrosion, and other challenges—tasks that ordinary materials often struggle to accomplish. However, IOTA 3301 Methylphenyl Raw Rubber, with its advantages of high/low temperature resistance, radiation resistance, and strong stability, has become a "reliable partner" for these special scenarios.

It is a type of macromolecular methylphenyl silicone oil, and the phenyl groups in its molecular structure are the "key to its performance". Depending on the difference in phenyl content, it exhibits targeted advantages:

- With low phenyl content, its low-temperature resistance is particularly prominent. Even in an ultra-low temperature environment of -110°C, it does not become stiff and brittle; instead, it maintains a certain degree of flexibility. Products made from it can work stably in scenarios such as polar exploration equipment and low-temperature refrigeration devices.

- With medium phenyl content, its damping performance is significantly improved, enabling it to effectively absorb vibration energy. It can be used in mechanical components and electronic devices that require shock absorption, reducing the impact of vibration on the equipment.

- With high phenyl content, its radiation resistance is greatly enhanced. It can maintain stable performance even in strong radiation environments, providing strong protection for aerospace equipment and components related to the nuclear industry.

In addition to these "specialized capabilities", it also has many universal advantages. It boasts excellent thermal stability—even when used for a long time in high-temperature environments, it is not prone to aging or decomposition, which extends the service life of products. It has low volatility and no odor, and does not release harmful gases during use, which not only meets environmental protection requirements but also ensures the health of operators. It also has strong storage stability; even after long-term storage, its performance does not decline significantly, reducing the difficulty of material management. Moreover, it has the property of being insoluble in water but soluble in solvents such as toluene. This allows it to maintain stability in humid environments while being easy to adjust its form according to construction needs, enabling it to be easily used in conjunction with other materials. After being made into finished products, it has low compression set and can withstand saturated vapor pressure. Even under high-pressure and humid working conditions, it can maintain its original shape and performance without being easily damaged.

Thanks to these outstanding properties, it plays an important role in a variety of special scenarios. In the aerospace field, it can be used to manufacture high/low temperature-resistant seals for spacecraft, coping with extreme temperature differences and radiation in space. In nuclear industry-related scenarios, the version with high phenyl content can resist radiation, protecting equipment components from radiation erosion. In the field of low-temperature storage, such as blood refrigeration and industrial low-temperature raw material storage, the version with low phenyl content can ensure that sealing materials work normally at low temperatures to prevent leakage. In the electronics industry, it is an excellent waterproof, moisture-proof, and insulating material, protecting precision electronic components from moisture and harsh environments. In the mechanical field, by virtue of its damping performance, it can be made into shock-absorbing components to improve the stability of equipment operation.

This methylphenyl raw rubber, which can cope with special scenarios and has comprehensive performance, undoubtedly provides a new solution for various industries to solve material problems in extreme environments, and has become an indispensable "reliable partner" in special scenarios.