When making pasta at home, many people focus on whether the dough mat is safe and durable. After all, it comes into direct contact with flour, so the material safety cannot be taken lightly, and at the same time, it must withstand repeated kneading, rolling, and pulling. The IOTA M20-306L addition-cure silicone rubber specially designed for dough mats is not only food-grade but also has the advantages of high strength and strong adhesion, making the dough mat both safe and durable.

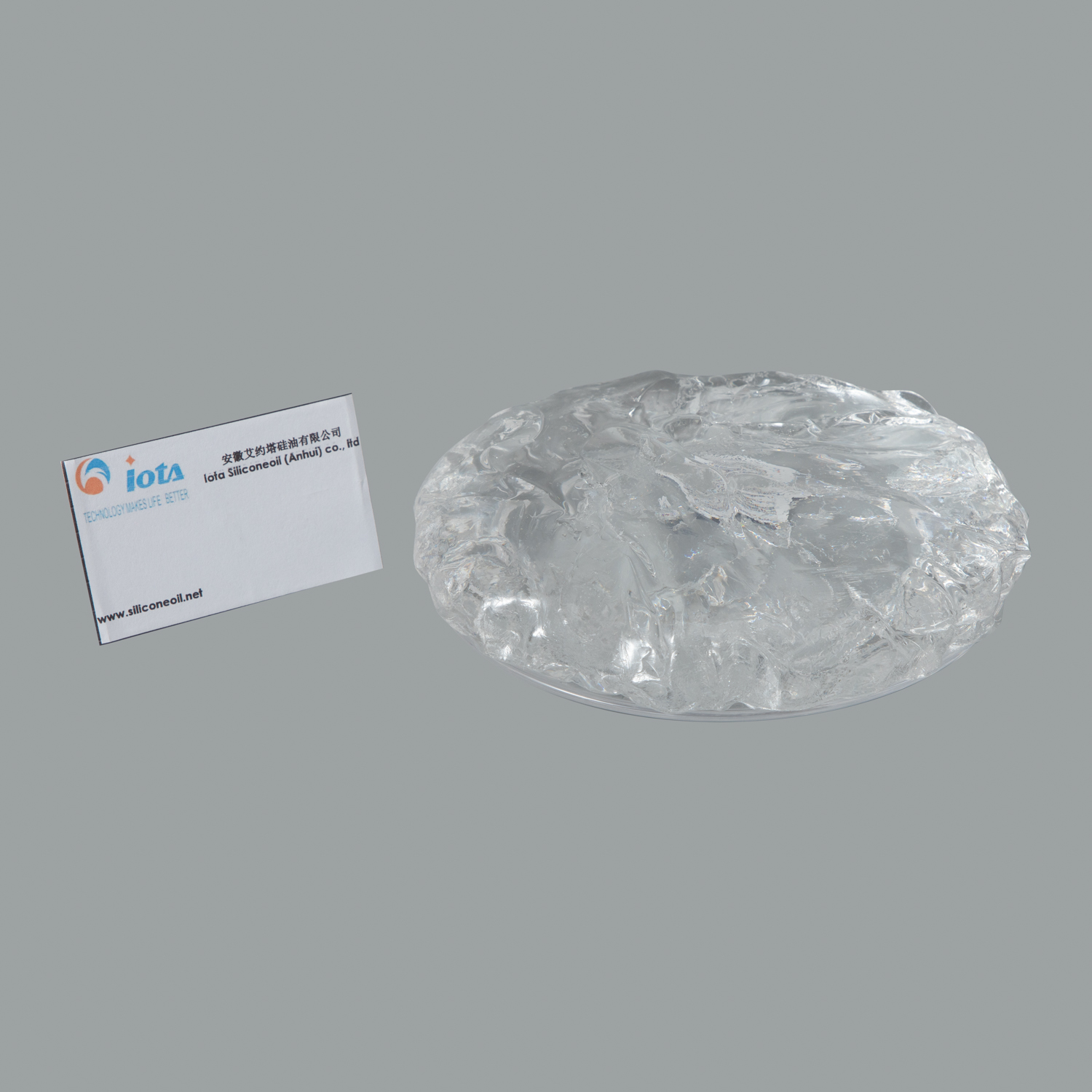

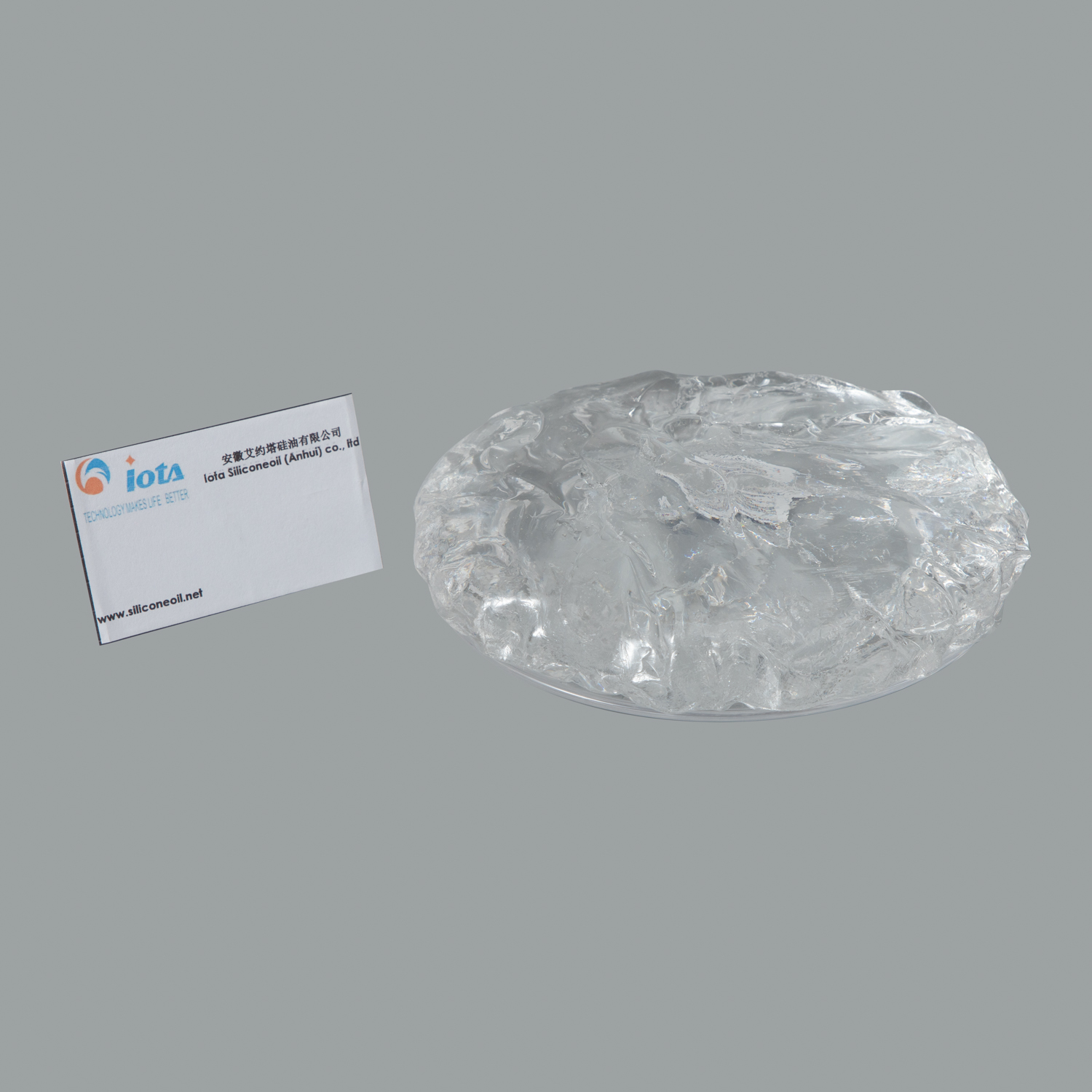

It adopts a two-component (Component A and Component B) design and can be used by mixing them in a weight ratio of A:B = 2:100. Component A is a transparent liquid with a viscosity of 1000 mPa·s after stirring at 23°C, similar to light syrup, which can be easily mixed evenly with Component B. Component B is translucent or slightly yellow with a higher viscosity, reaching 65000 mPa·s after stirring at 23°C. The mixed material has a viscosity of 60000 mPa·s, which can be easily applied to the substrate surface by doctor blading or dip coating to form a uniform film. It will not flow due to being too thin, resulting in excellent molding effects when making dough mats.

As a material specially used for dough mats, its core highlight is being "food-grade", which means it contains no harmful substances and is safe for direct contact with food ingredients such as flour and dough. Parents can use it with confidence when making complementary foods for their children, and the elderly can also use it safely when making steamed buns. Moreover, it has excellent adhesion to the substrate. After coating, it can firmly adhere to the substrate without delamination or peeling. Even with long-term and repeated use, the surface of the dough mat will not wrinkle or crack, achieving maximum durability.

The performance after curing is even more reassuring. It has a hardness of Shore A 40, providing sufficient support so that it will not deform easily when rolling the dough, while also having a certain degree of flexibility so that it will not break when rolled up for storage. Its tensile strength is ≥6 MPa, enabling it to withstand large pulling forces. Even if you pull the edge of the dough mat hard, it will not break easily. The elongation rate is ≥300%, meaning the dough mat can rebound quickly after being pulled and will not remain in a stretched state, thus maintaining its original shape even with long-term use. The tear strength is ≥10 kN/m, so it is not prone to cracks when subjected to repeated rolling by a rolling pin and friction from the dough, greatly extending its service life.

In addition to making dough mats, it can also be used for other doctor-blading and dip-coating products, such as protective coatings for food contact applications. However, it should be noted that it is a platinum-catalyzed product, so catalyst poisoning should be avoided during use. If coloring of the product is required, the colorant should be added to Component B and stirred evenly before mixing with Component A.

This silicone rubber, which integrates safety, durability, and ease of processing, undoubtedly provides a high-quality material option for the production of food contact products such as dough mats, making it more reassuring and worry-free for everyone to make pasta at home.