Injection-molded products span industries such as automotive, electronics, healthcare, and consumer goods, each with vastly different material requirements—some demand extreme softness, others require durability and wear resistance, while some prioritize rapid curing or eco-friendliness without odors. A multi-grade, high-performance non-secondary vulcanization liquid silicone rubber, with its exceptional adaptability and comprehensive advantages, breaks through application limitations and opens up new possibilities for innovation in injection-molded products.

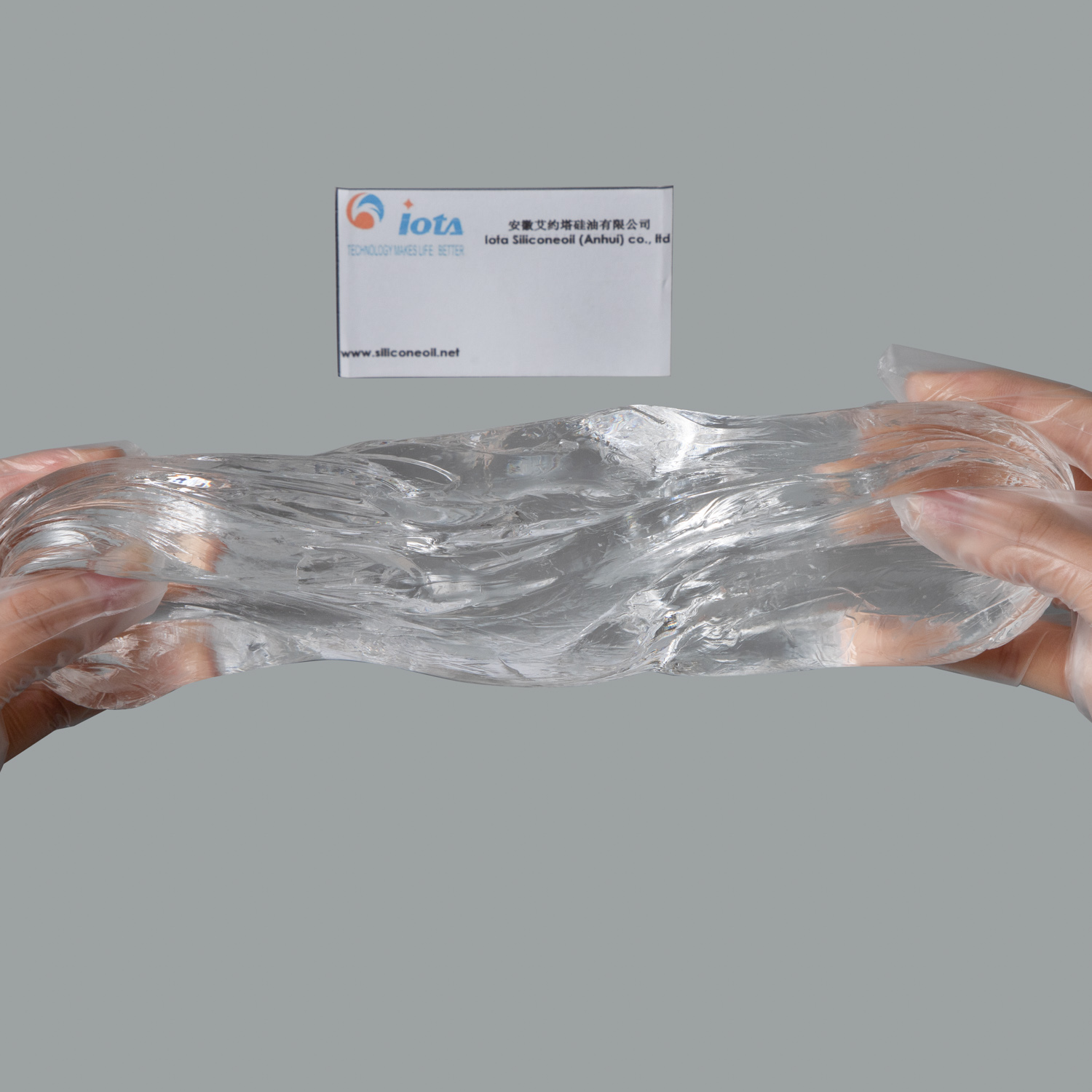

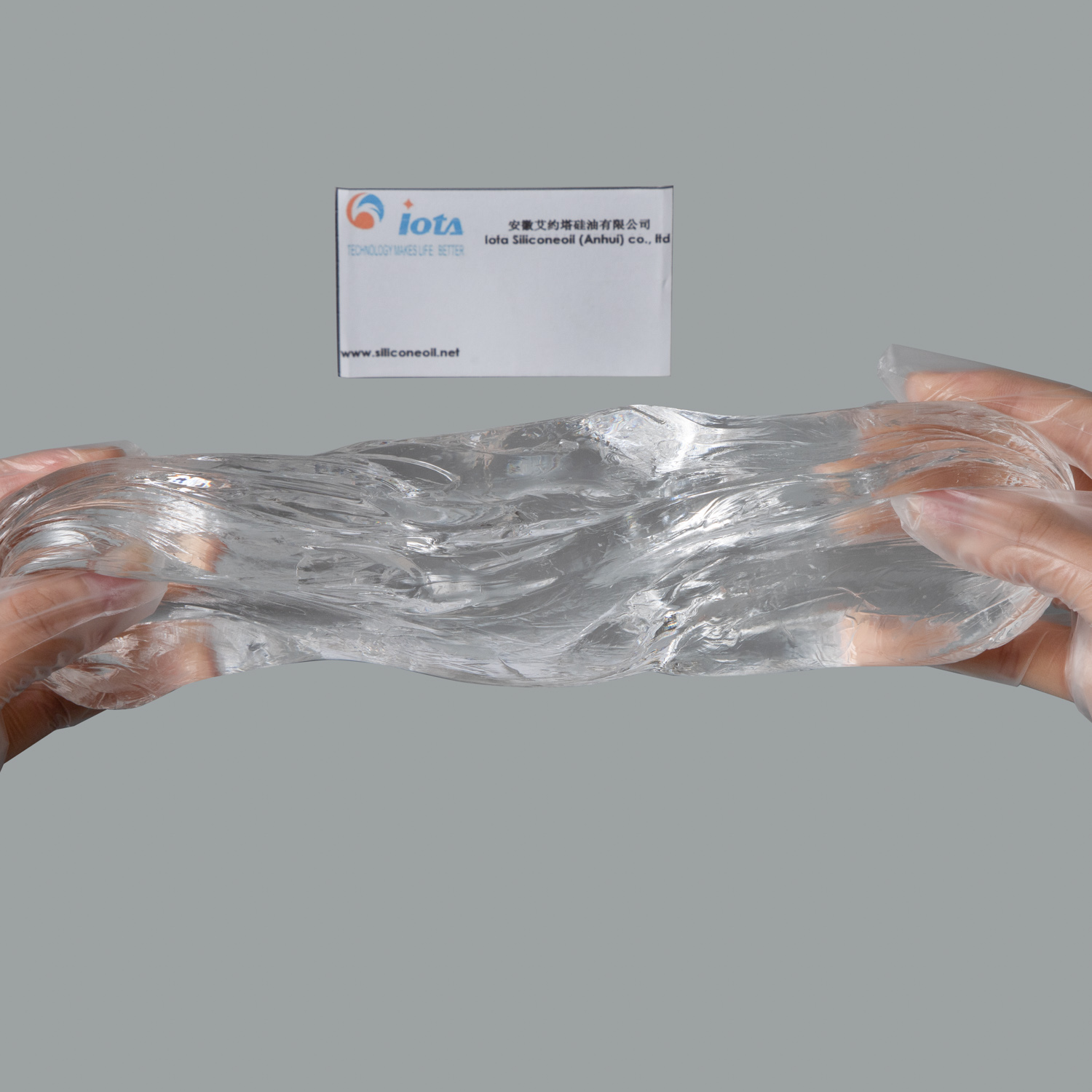

This product offers three distinct grades corresponding to hardness levels of 40, 50, and 60 Shore A, each precisely tailored to meet industry-specific needs. The 3040 grade provides moderate hardness with excellent flexibility and an elongation rate of up to 580%, making it ideal for flexible components that undergo frequent bending, such as waterproof seals for electronic devices and soft connectors for medical supplies. The **3050 grade** balances performance with a tensile strength of 10 MPa and tear strength of 40 kN/m, combining softness and durability. It is well-suited for automotive door seals and non-slip components in fitness equipment. The **3060 grade**, with its higher hardness and enhanced stability, is designed for injection-molded products requiring strong support, such as sealing gaskets for industrial machinery and rigid silicone accessories for kitchenware.

The product's versatility extends to its operational and production simplicity. Its two-component 1:1 mixing ratio ensures uniform blending without the need for complex equipment, making it adaptable to both small-scale workshops and large-scale factory production. Its rapid-curing properties further enhance production flexibility—curing in 90 seconds at 130°C and 45 seconds at 150°C—allowing manufacturers to adjust production schedules efficiently, shorten delivery times, and handle varying order volumes.

Its environmental and safety performance meets the stringent requirements of high-demand applications. With a low VOC content of less than 0.5%, it is odorless, pollution-free, and complies with environmental regulations, making it suitable for industries like healthcare and electronics. The high-adhesion feature ensures outstanding performance in composite products, offering strong bonding with substrates such as metal, plastic, and glass, and reducing the risk of detachment. This enhances the overall stability and longevity of finished products. For example, silicone seals for automotive engines maintain secure sealing even under high temperatures, preventing leaks.

From core automotive components and precision electronic parts to disposable medical supplies and everyday consumer goods, this non-secondary vulcanization high-adhesion liquid silicone rubber, with its multiple grades, comprehensive performance, and broad adaptability, serves as a critical material for industries aiming to enhance product quality and innovate product designs. It continues to inject new vitality into the injection-molded product industry.