Flame-Retardant and Antistatic Addition-Cure Silicone Rubber IOTA LSR 3M20-50W-1

Addition-Cure Silicone Rubber IOTA LSR 3M20-50 Specialized for High-Strength Fireproof Cloth

Addition silicone rubber for High-strength fireproof cloth ( low-viscosity coating)IOTA LSR 3420-40T

Mold-Resistant Addition-Cure Silicone Rubber IOTA LSR 3M20-50W-0

Addition silicone rubber for High-strength fireproof cloth ( solvent-free coating) IOTA LSR 3352

Product Introduction:

IOTA LSR 3M20-50 is a low-viscosity, addition-cure silicone rubber specifically designed for high-strength fireproof cloth applications.

Key Features:

Excellent thixotropy, ensuring good moldability and high efficiency.

Good adhesion to fiberglass cloth.

High strength and flame retardancy.

Typical Applications:

Specialized adhesive for fireproof cloth.

Other products suitable for scraping and dip coating.

Important Notes:

IOTA LSR 3M20-50 is catalyzed with platinum; the platinum catalyst is in Component A. Strict precautions must be taken to avoid catalyst poisoning.

If coloring is required, it must be added to Component B, mixed thoroughly, and then combined with the measured amount of Component A.

Product Specifications:

|

Property |

Test Method |

Value |

|

Uncured Product |

|

|

|

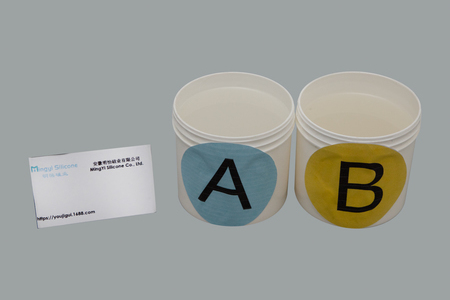

Component A |

|

|

|

Color |

|

White |

|

Viscosity at 23°C, after stirring (mPa.s) |

ISO3219 |

100000mPa.s |

|

Component B |

|

|

|

Color |

|

White |

|

Viscosity at 23°C, after stirring (mPa.s) |

ISO3219 |

80000mPa.s |

|

Product Data (A+B Mixed) |

|

|

|

Mixing Ratio |

A:B |

1:1 |

|

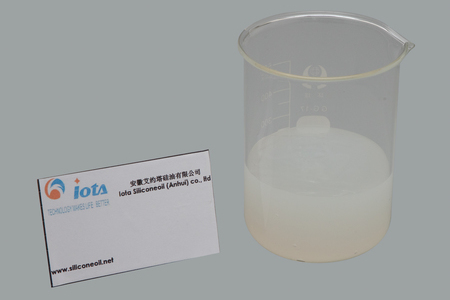

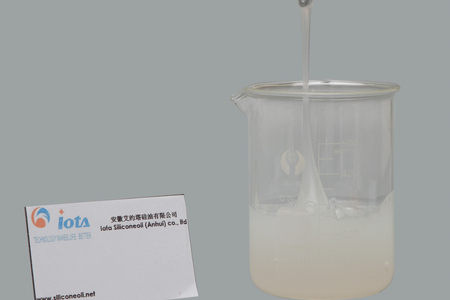

Viscosity at 23°C, after stirring (mPa.s) |

ISO3219 |

85500mPa.s |

|

Product Data (Cured) |

|

|

|

Color |

|

White |

|

Hardness (Shore A) |

DIN 53505 |

50 |

|

Tensile Strength |

DIN 53504 |

5.5MPa |

|

Elongation (%) |

DIN 53504 |

250 % |

|

Tear Strength |

ASTMD 624B |

16KN/m |

All values are characteristic and should not be accepted as standard specifications.

Packaging:

Component A: 2 Kg/pail

Component B: 200 Kg/pail

Storage and Shelf Life:

Store below 23°C. Unopened pails have a shelf life of 12 months. The best-before date is marked on the label of each product's outer packaging. Although the material may still be used beyond this date, performance testing of relevant indicators is necessary to ensure quality.