Is it hard to clean stains on your home sofa leather? Has your car seat lost its luster after long use? A surface treatment agent specially developed for leather is revitalizing various leather products with its dual properties of "silky texture + super stain resistance," becoming a "leather care artifact" in fields such as furniture and automobiles.

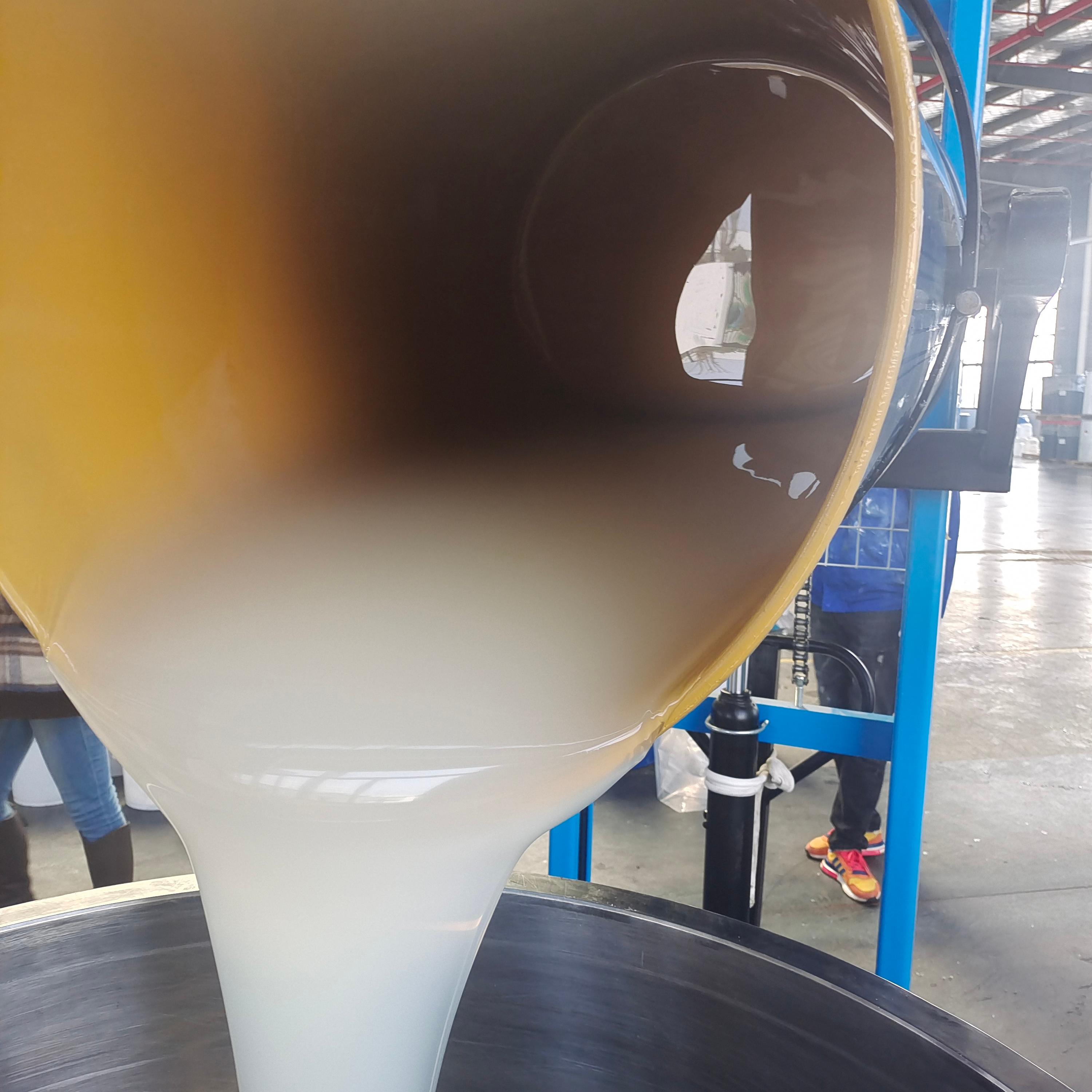

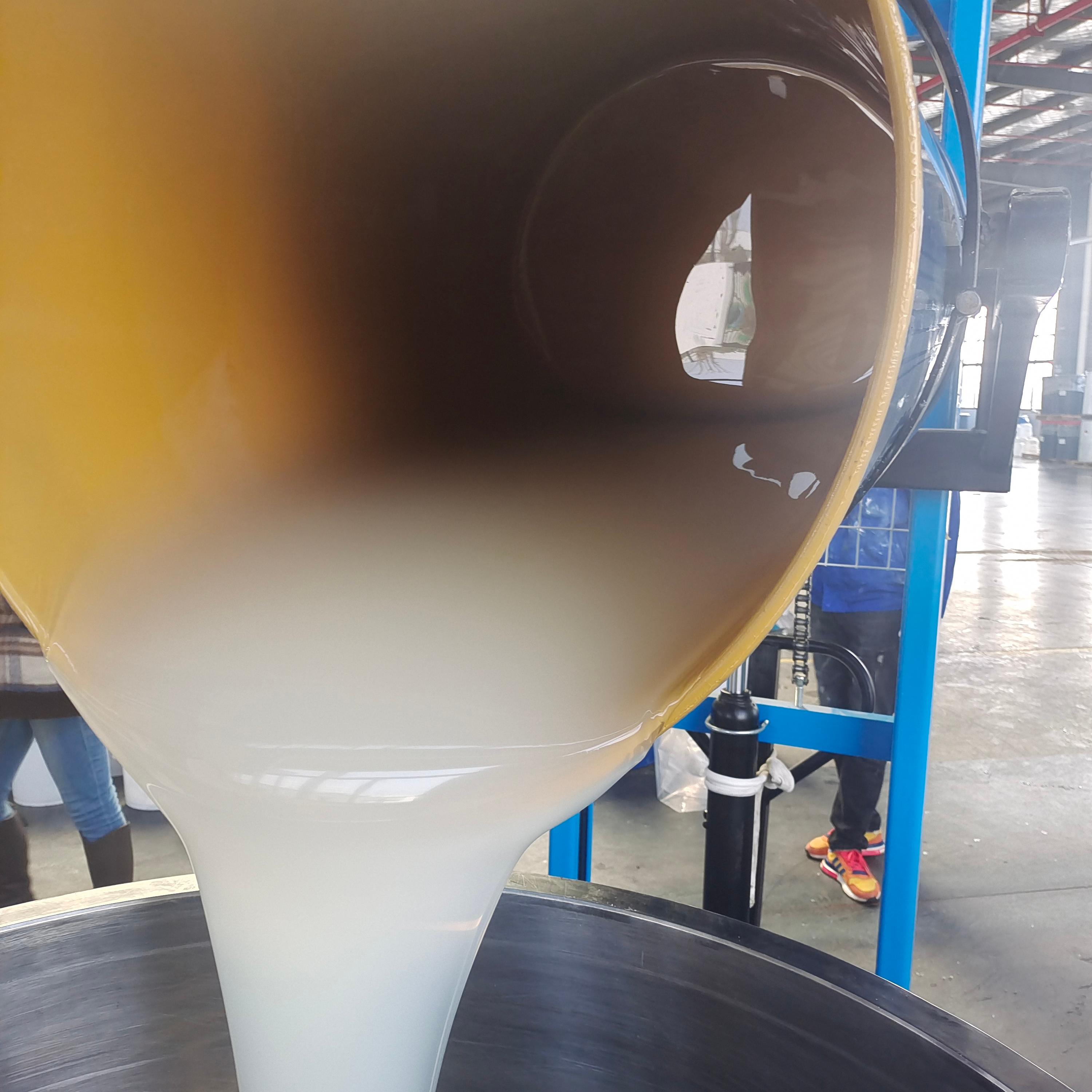

The most intuitive advantage of this treatment agent is that it gives leather a "silky coat." The treated leather surface feels soft and delicate, as smooth as velvet, completely bidding farewell to rough and stiff textures. Whether it’s the contact surface of furniture sofas or the leather surface of car seats, it delivers a warm and comfortable skin-like experience, making daily use more textured. Its light white translucent liquid texture does not alter the original color of the leather, and after treatment, it enhances the surface gloss, making old leather look brand new.

The stain resistance capability solves a major problem in leather maintenance. Common stains like marker or ballpoint pen marks on treated leather can be easily wiped off with a gentle rub, eliminating the hassle of stubborn stains. Liquid stains such as coffee or oil are also less likely to penetrate; they form water droplets on the surface and roll off, reducing the chance of deep infiltration into the leather and greatly lowering cleaning difficulty. This stain-resistant feature simplifies leather furniture maintenance for families with children or pets.

Its application range is very wide, suitable for silicone leather products such as furniture leather, automotive leather, clothing fabrics, and 3C electronic soft covers. The viscosity of different models can be flexibly adjusted between 200-2500 to adapt to the surface characteristics and treatment needs of different leathers. During construction, it only takes 5 minutes to cure at 130-150°C, making the operation convenient and efficient, suitable for large-scale production and processing.

For manufacturers, its solvent resistance is also important—it can resist erosion from daily cleaning agents, ensuring long-term stability of the treatment effect. The 25%-30% solid content design makes the material more efficient to use, forming a uniform protective film without causing waste. Whether it’s pre-treatment for new leather products or renovation and maintenance of old leather, this treatment agent helps leather maintain a silky texture and stain resistance, extending its service life.