In the material market, high-molecular-weight hydroxyl-terminated silicone raw rubber (IOTA 107GUM) is definitely a "hot commodity"—it is indispensable in multiple industries such as electronics, textiles, automotive, and construction. What exactly makes it so popular? The answer lies in its robust performance and exceptional adaptability.

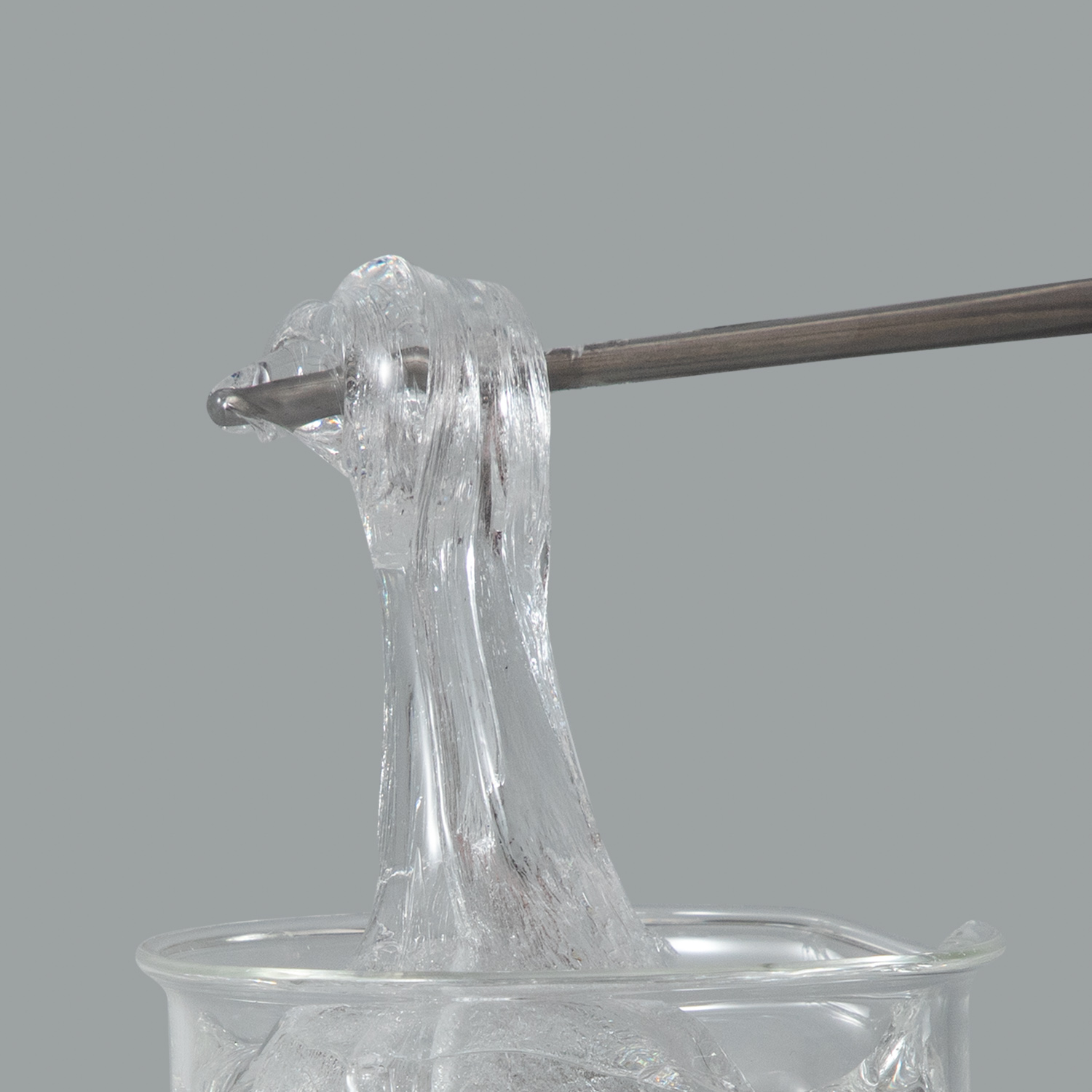

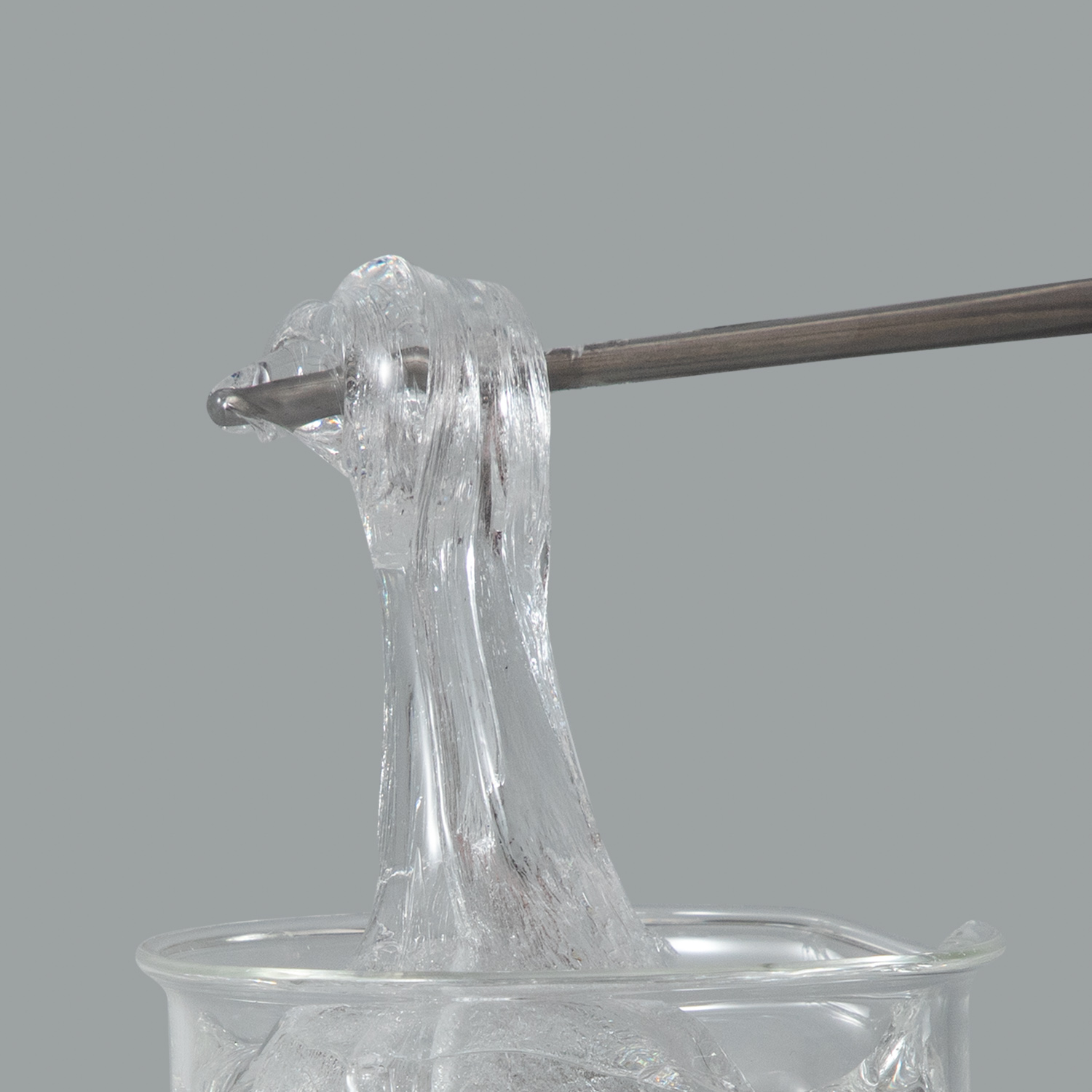

First, its "basic attributes" are already impressive: it appears as a colorless, transparent semi-solid with no impurities at all. During processing, it will not cause color or appearance issues to the finished products. For example, when used to make transparent electronic sealants or light-colored cashmere sweaters, it can maintain a pure appearance. With a purity of over 99%, it means there are almost no "excess components"—when used as a raw material, the performance of the finished products will be extremely stable, without fluctuations in quality. Its molecular weight ranges from 400,000 to 1,000,000, placing it among the "top performers" in high-molecular-weight materials. Its long molecular chains and stable structure are like strong, elastic "ropes"—whether processed into rubber, sealants, or smoothing agents, it can maintain excellent performance.

More importantly, its "special strengths" can accurately meet the needs of multiple industries. The first "strength" is its excellent electrical insulation, which has secured its position in the electronics sector. When made into potting and sealing materials, it can provide a "moisture-proof and insulating coat" for radios, electronic instruments, and semiconductor components. Even if electronic devices are in a humid environment, it can prevent component short circuits. At the same time, it can resist high temperatures and buffer vibrations—for instance, electronic components in automobiles can operate stably with its protection, even amid the high temperatures from the engine and the jolts of driving.

The second "strength" is its good reactivity and flexibility, making it a "core raw material" for rubber products. In the production of RTV silicone rubber and pressure-sensitive adhesives, it can react efficiently with other components to produce rubber with good elasticity and high strength. The automotive and machinery industries use it to make rubber rollers—thanks to its wear resistance, the rollers can last longer. Even when making two-component silicone rubber molds, it can help the molds release easily while ensuring clear mold details, making it particularly suitable for manufacturing high-precision stamps.

The third "strength" is its ability to improve texture, which has made it highly popular in the textile industry. As a wool and cashmere smoothing agent, a small amount of it is enough to make rough wool fibers soft and smooth. The treated fibers feel comfortable to the touch and do not irritate the skin when worn, making high-end wool and cashmere products more favored by consumers.

The construction industry also cannot do without it—the joint sealant made from it can tightly fill gaps, providing waterproofing and anti-aging effects, and reducing the need for frequent gap repairs in buildings.