In product design, material performance is often a "fixed answer"—pursuing low-temperature resistance may mean sacrificing high-temperature resistance, and seeking radiation resistance may lead to the loss of flexibility. However, the IOTA120 methylphenylvinyl silicone rubber enables performance customization by adjusting phenyl content, freeing designers from the "either-or" dilemma and giving them more creative freedom.

The core of its performance customization lies in the flexible adjustment of phenyl content, ranging from 5% to 40% (Ph/Si): when the phenyl content is low, the material focuses on "superior cold resistance", able to maintain soft elasticity in extremely cold environments, making it suitable for designing seals for outdoor equipment in northern regions and protective covers for low-temperature pipelines; when the phenyl content is increased to a medium-high level, "ablation resistance" becomes its core advantage, which can be used to design industrial furnace linings and high-temperature-resistant components for aerospace vehicles; when the phenyl content reaches a high level, "radiation resistance" performance is activated, allowing the design of protective coatings for nuclear medical equipment and casings for electronic components in radiation environments.

This "customization on demand" feature means designers do not have to compromise to adapt to material performance. For example, when designing a seal for an outdoor sensor that needs to handle temperature differences between northern and southern regions, simply selecting a low-phenyl-content model allows it to cope with both the subzero cold in the north and the high-temperature exposure in the south; when designing multi-scenario components for aerospace vehicles, materials with different phenyl contents can be chosen according to the needs of different parts—this not only ensures ablation resistance and radiation resistance for key parts but also maintains flexibility in non-critical parts, reducing overall costs.

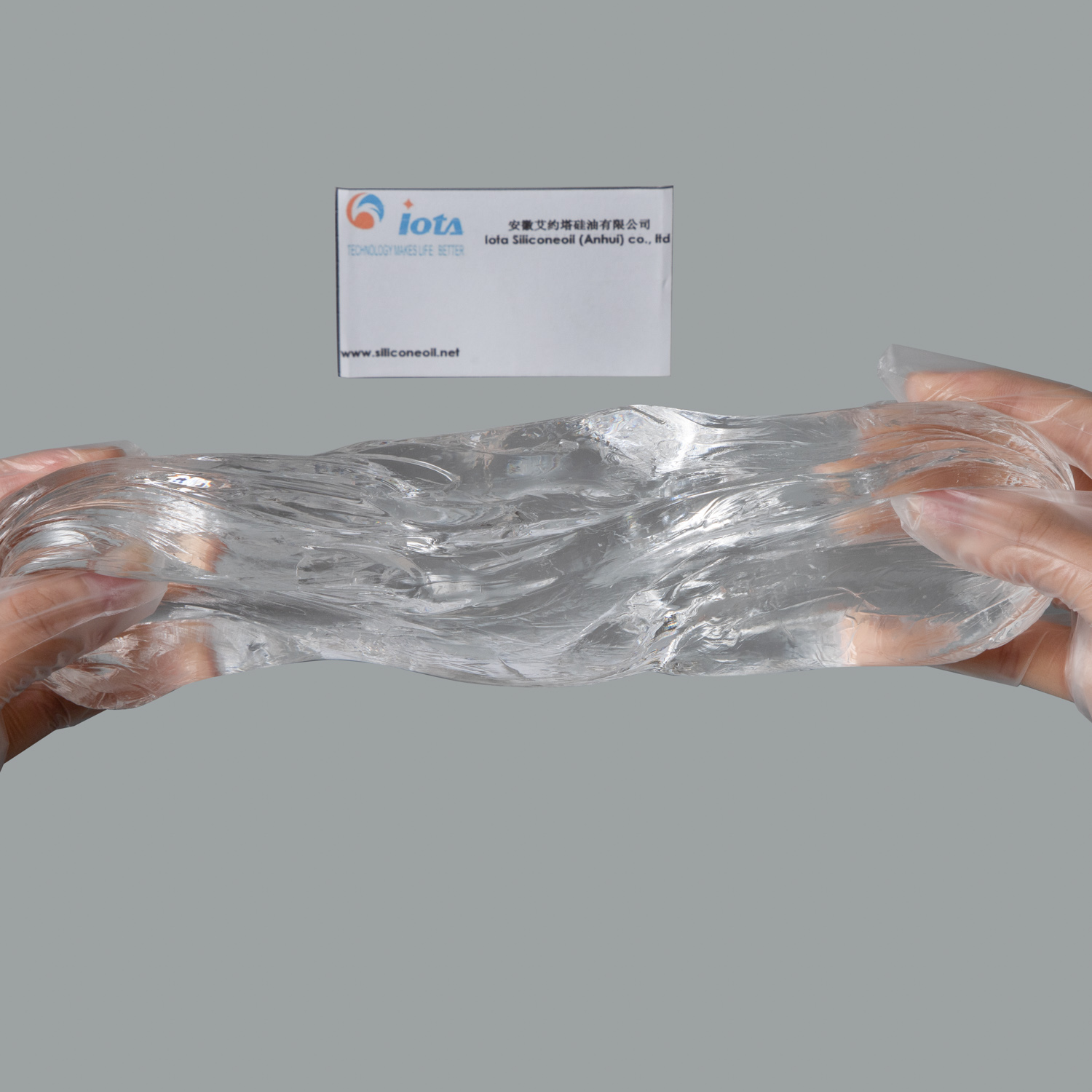

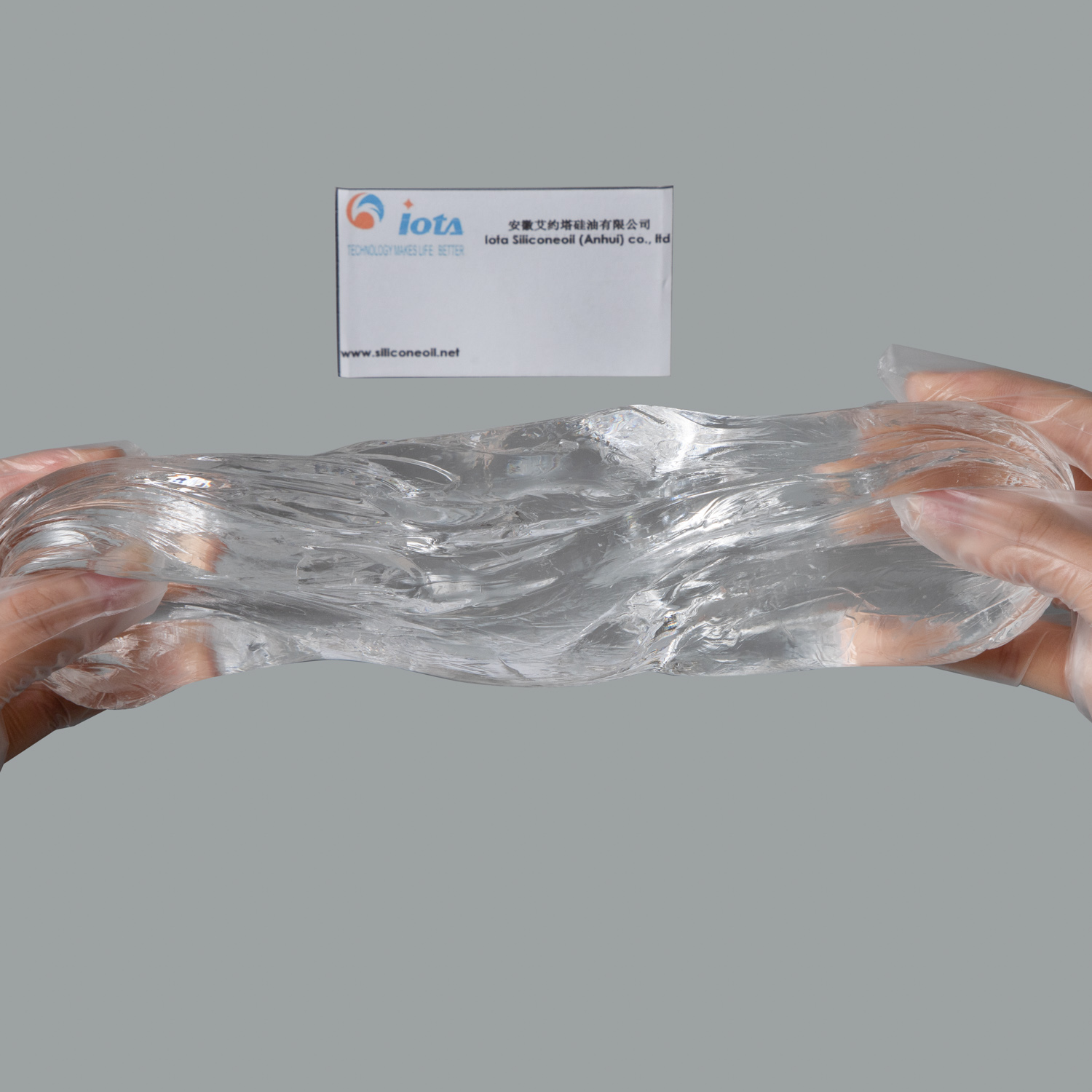

In addition to being customizable, its basic qualities can also support diverse design needs. Its colorless appearance can be easily matched with various color schemes without affecting the product's aesthetics; its lightweight texture does not add extra burden to small equipment and precision instruments; its low volatile content means it will not release harmful substances even when made into components for enclosed spaces; as a base rubber for high-temperature vulcanized silicone rubber, it is compatible with a variety of auxiliary materials, and can be easily made into different forms such as seals, coatings, and molded products.

For storage, it only needs to be placed in an environment below 40℃, with an unopened shelf life of 1 year, and no complicated processing is required for subsequent use. This silicone rubber, which can "adapt to design", provides more possibilities for product innovation, ensuring that great designs are no longer limited by material performance.