In high-risk scenarios such as aerospace, nuclear industry, and high-temperature industry, materials must not only withstand high-temperature ablation but also resist radiation erosion—ordinary materials often "can't stand the test". However, IOTA120 Methyl Phenyl Vinyl Silicone Rubber, relying on ablation resistance brought by medium-to-high phenyl content and radiation resistance from high phenyl content, has become a "safety guardian" for high-risk scenarios.

Its ablation resistance is truly "high-performance"—with medium-to-high phenyl content, the material not only does not burn easily when exposed to high-temperature ablation but also forms a heat-insulating protective layer to block heat penetration inward, protecting the substrate from damage. For example, when used as a protective coating for spacecraft engine nozzles, it can remain stable under the scouring of thousands of degrees of high-temperature gas, preventing the nozzle from being damaged by ablation; when used as a seal for industrial furnace doors, it will not melt or deform even after long-term contact with high-temperature furnace gas, ensuring stable temperature inside the furnace and reducing energy waste.

The radiation resistance of the high phenyl content version is even more "timely help". In nuclear medical equipment and nuclear industry instruments, the radiation environment accelerates material aging and failure, but this silicone rubber can resist radiation erosion and will not experience performance degradation, embrittlement, or cracking even when in a radiation environment for a long time. For instance, when made into seals for equipment around nuclear reactors, it can ensure the equipment maintains a good seal under radiation, preventing the leakage of harmful substances; when used to produce protective components for radiation therapy instruments, it can reduce radiation damage to internal components of the instruments, extending their service life.

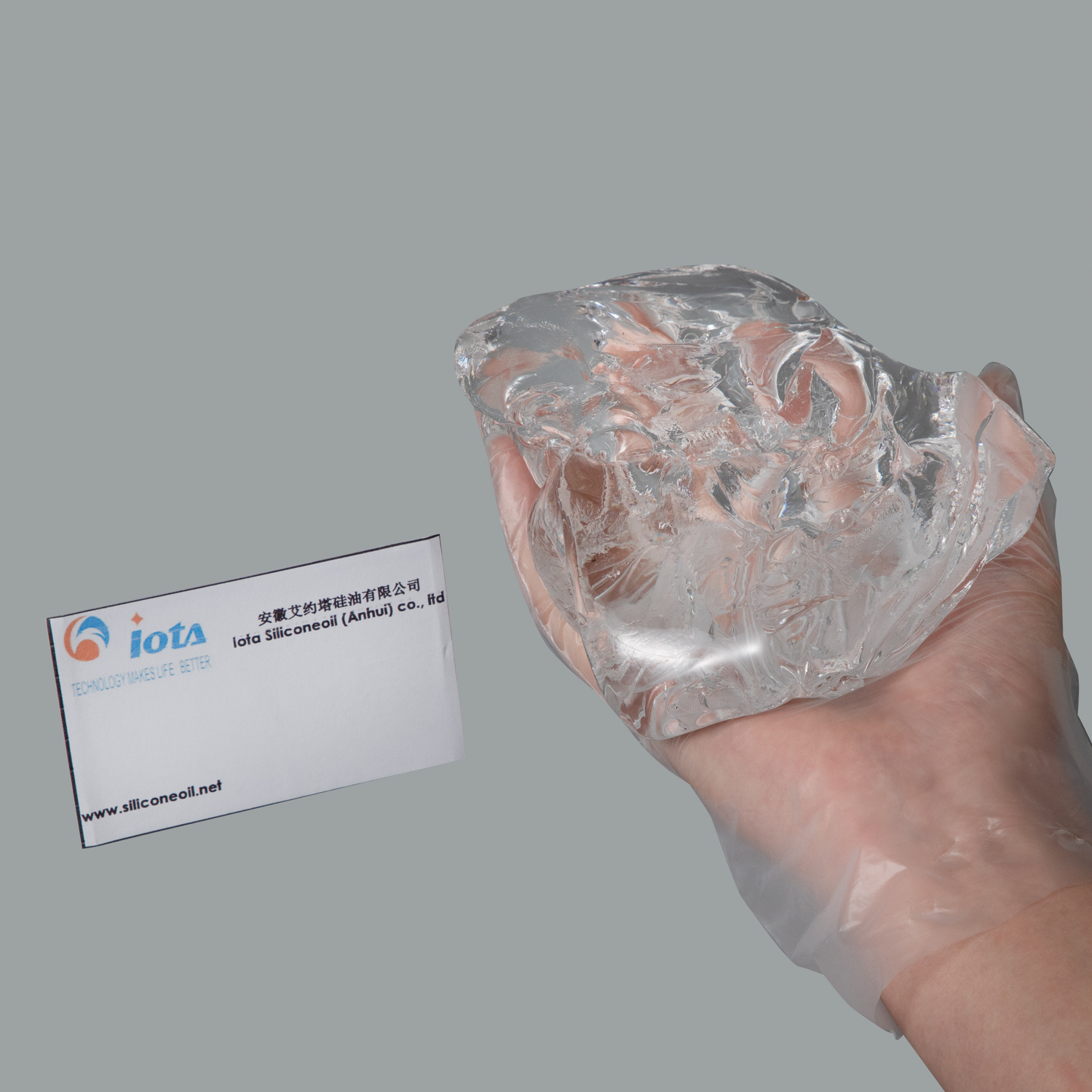

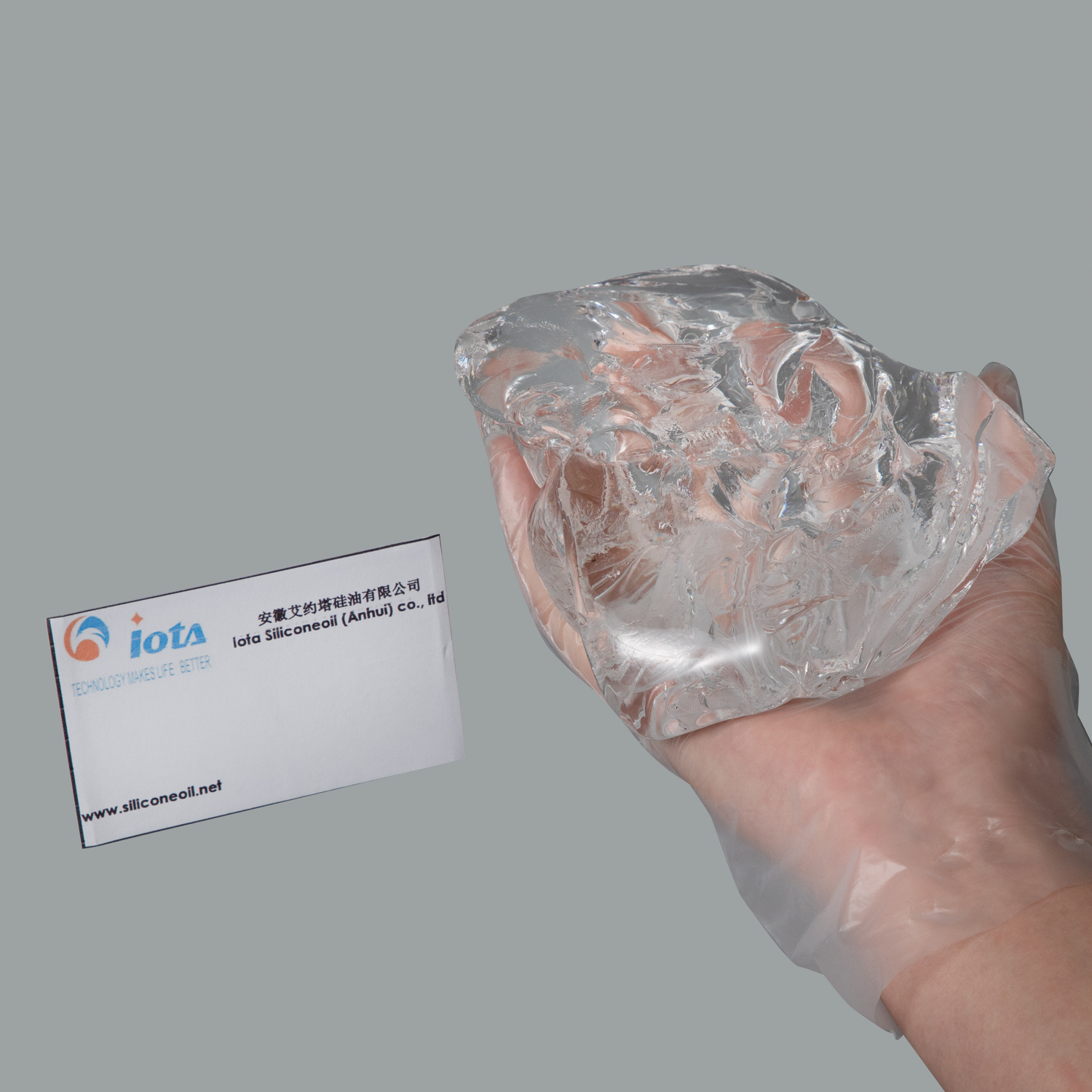

What's more remarkable is that while possessing high-risk protection capabilities, it also maintains excellent resistance to high and low temperatures, enabling stable operation under extreme temperature differences and adapting to complex temperature changes in high-risk scenarios. Its colorless appearance does not affect equipment identification and observation; its low volatile content prevents the release of harmful substances in closed high-risk environments; as a high-temperature vulcanization base rubber, it can be made into products of different forms to meet diverse needs such as sealing, protection, and insulation.

No special conditions are required for storage and use—it only needs to be stored below 40°C, and it can still be used if it passes the inspection after expiration. This silicone rubber that can "stand its ground" in high-risk scenarios provides important protection for equipment safety and personnel safety, becoming an indispensable high-quality material in high-risk industries.