In fields such as aviation and electronics, equipment often faces extreme environments like ultra-low temperatures and strong radiation. Ordinary materials either become frozen and brittle or fail under the influence of radiation. However, IOTA 3301 Methylphenyl Raw Rubber, with its unique properties, has become a "reliable companion" in extreme environments.

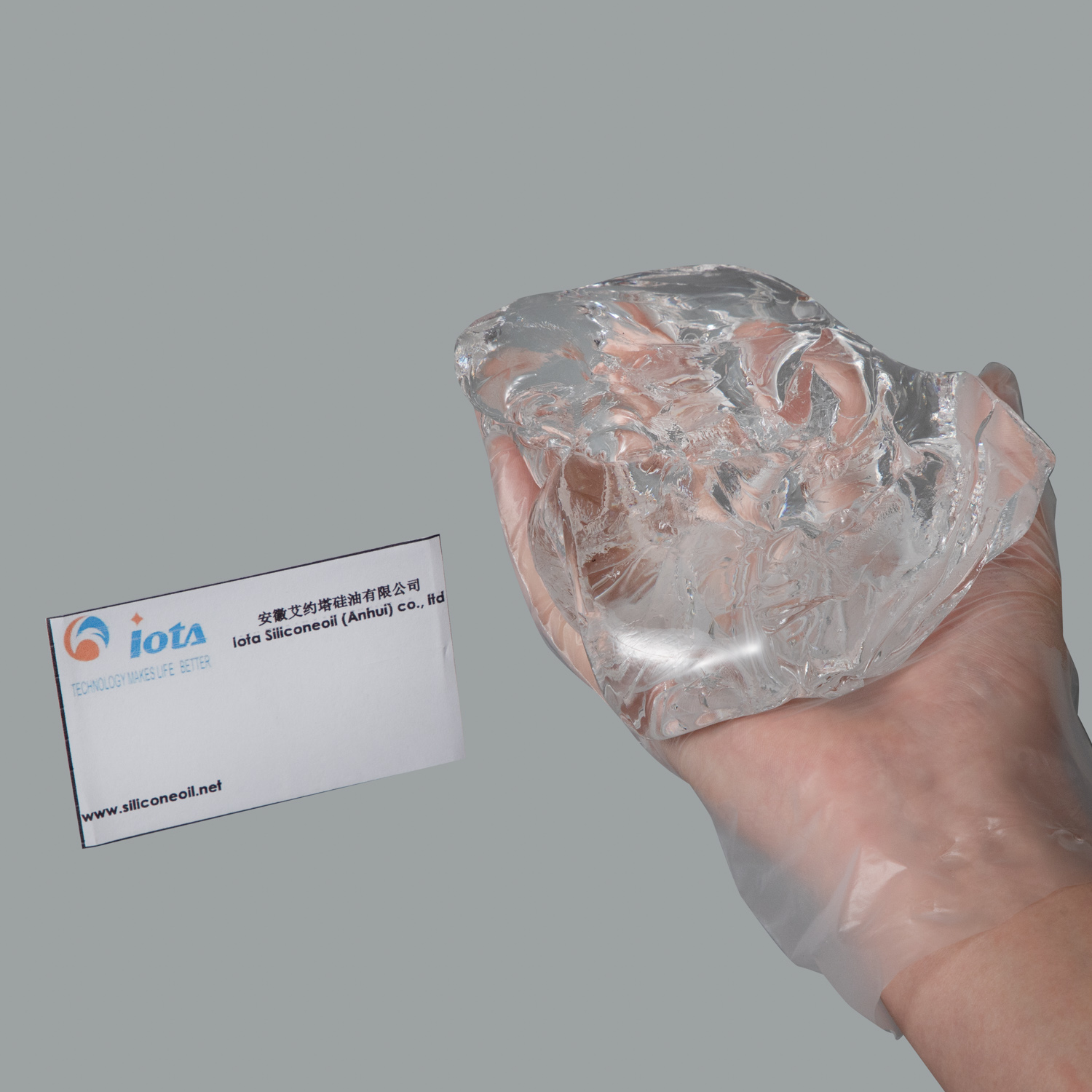

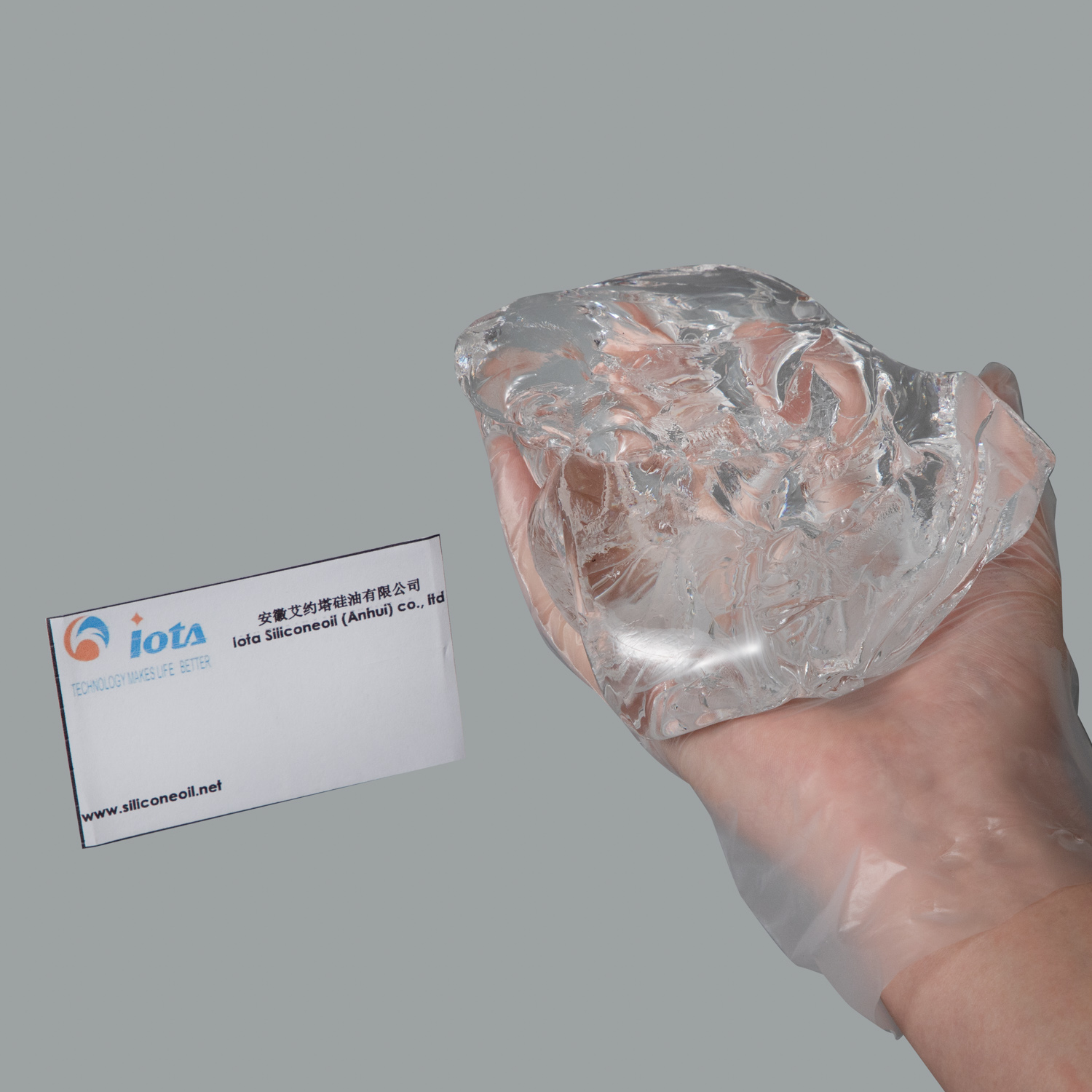

Essentially, it is a macromolecular methylphenyl silicone oil, and its molecular structure contains a large number of phenyl groups—this is the key to its outstanding performance. More notably, the phenyl content acts like a "function adjustment switch", allowing it to accurately meet different needs:

- When the phenyl content is low, its low-temperature resistance is maximized. Even at an ultra-low temperature of -110°C, it still maintains flexibility and does not break rigidly like ordinary materials. Parts made from it can work stably in cold regions or low-temperature equipment.

- When the phenyl content is medium, its damping performance is significantly improved. It can absorb vibration and reduce noise like a "shock pad", making it particularly suitable for mechanical components.

- When the phenyl content is high, its radiation resistance becomes prominent. Even if it is in a radiation environment for a long time, its performance does not degrade, building a "protective barrier" for aerospace and nuclear-related equipment.

In addition to its targeted advantages, its "universal capabilities" are also impressive. It has excellent thermal stability and does not easily deteriorate at high temperatures. It has low volatility and no odor, and does not release harmful substances during use, making it both environmentally friendly and safe. Its performance remains stable even after long-term storage, so there is no need to worry about sudden failure. Furthermore, it is insoluble in water but soluble in solvents such as toluene. During construction, its form can be flexibly adjusted, facilitating its combination with other materials. After being made into products, it has low compression set and can withstand saturated vapor pressure. Even in humid and high-pressure environments, it can maintain its original state without being easily damaged.

Relying on these advantages, it has made remarkable contributions in multiple fields. In the aviation field, it can be used to produce high/low temperature-resistant sealing materials to cope with extreme temperature differences at high altitudes. In the electronics industry, it is an excellent waterproof and moisture-proof insulating material, protecting circuit boards from moisture. In the mechanical field, its damping performance enables it to be made into shock-absorbing components, making equipment operation more stable. In the chemical industry, its characteristics of corrosion resistance and tolerance to extreme working conditions come into play. What is even more remarkable is its physiological inertness, which allows it to cross into the medical field—it can be used for blood refrigeration sealing to ensure the safety of blood storage, and for manufacturing medical tubes that do not cause adverse reactions when in contact with the human body.

This methylphenyl raw rubber, which is adaptable to multiple scenarios, undoubtedly provides a new solution for various industries to solve material problems in extreme environments, allowing more equipment to operate with peace of mind even under complex conditions.