Many people have encountered such a problem: a newly bought dough mat develops cracks shortly after use, or deforms and cannot recover after being pulled hard. However, the IOTA M20-306L addition-cure silicone rubber specially designed for dough mats, with its excellent toughness and tear resistance, frees dough mats from the "trouble of easy damage" and becomes a great helper for home baking and pasta making.

From the perspective of material properties, its "durability genes" run through it all. After curing, its tensile strength is ≥6 MPa, which means it can withstand large external pulling forces without breaking. For example, if you accidentally pull the edge of the dough mat while kneading the dough, you don't have to worry about it breaking directly. The elongation rate is ≥300%, so even if the dough mat is stretched to more than three times its original length, it can rebound quickly after being released without leaving permanent deformation marks. You can roll it up casually for storage without affecting its subsequent use. The tear strength is ≥10 kN/m, so the surface is not prone to small cracks when subjected to repeated rolling by a rolling pin and repeated kneading of the dough. Even if you occasionally use a sharp scraper to assist in organizing the dough, it is not easy to be scratched. Its durability is far superior to that of dough mats made of ordinary materials.

What's more reassuring is that it is a food-grade material, fully complying with food contact safety requirements. It will not release harmful substances when in direct contact with food ingredients such as flour, eggs, and butter, so families with the elderly and children can use it with peace of mind. In addition, it has good adhesion to the substrate. When making a dough mat, it can closely adhere to the surface of the substrate, avoiding separation between the coating and the substrate and wrinkling during use. It always maintains a flat surface for use, making the rolling of the dough smoother and preventing uneven thickness of the dough due to an uneven surface.

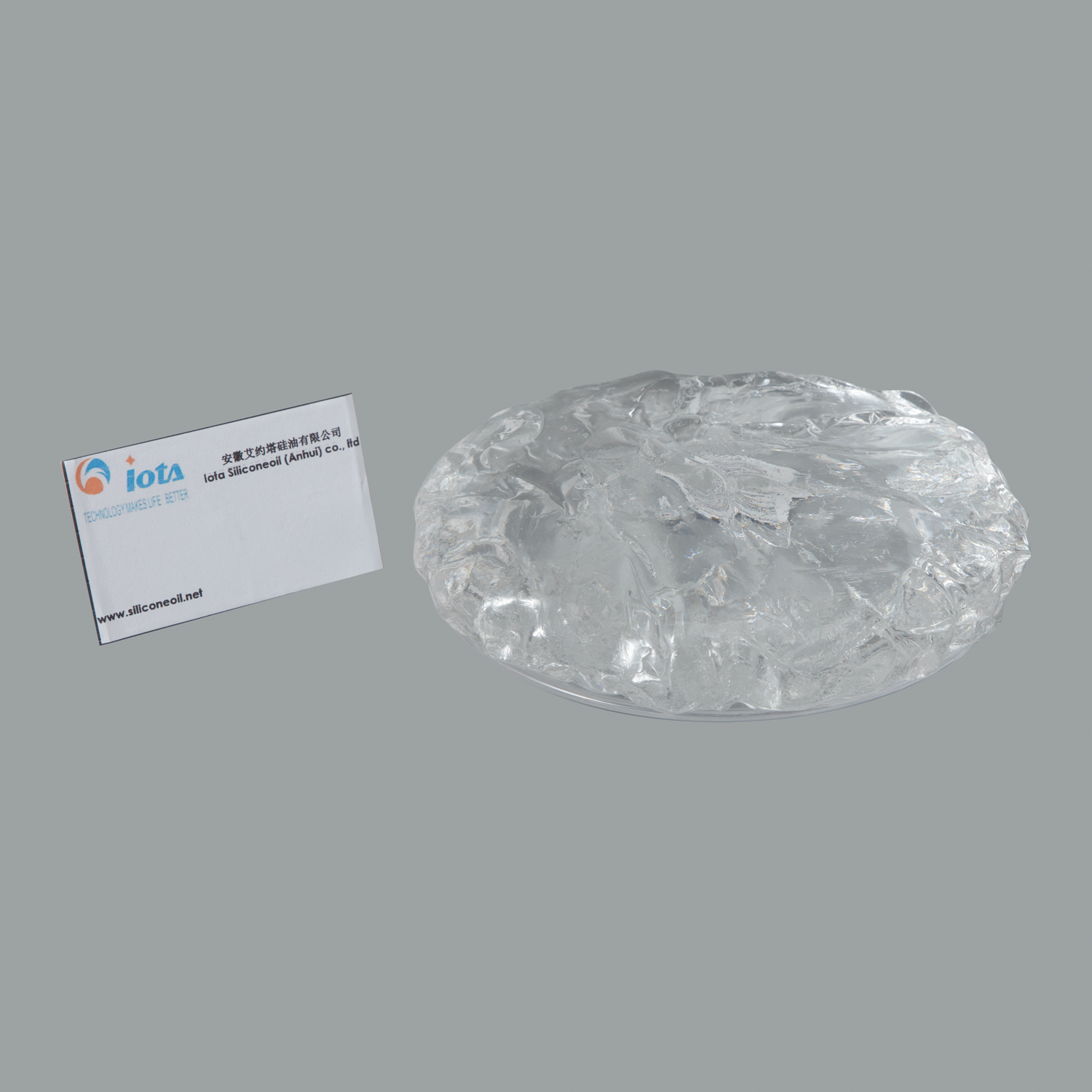

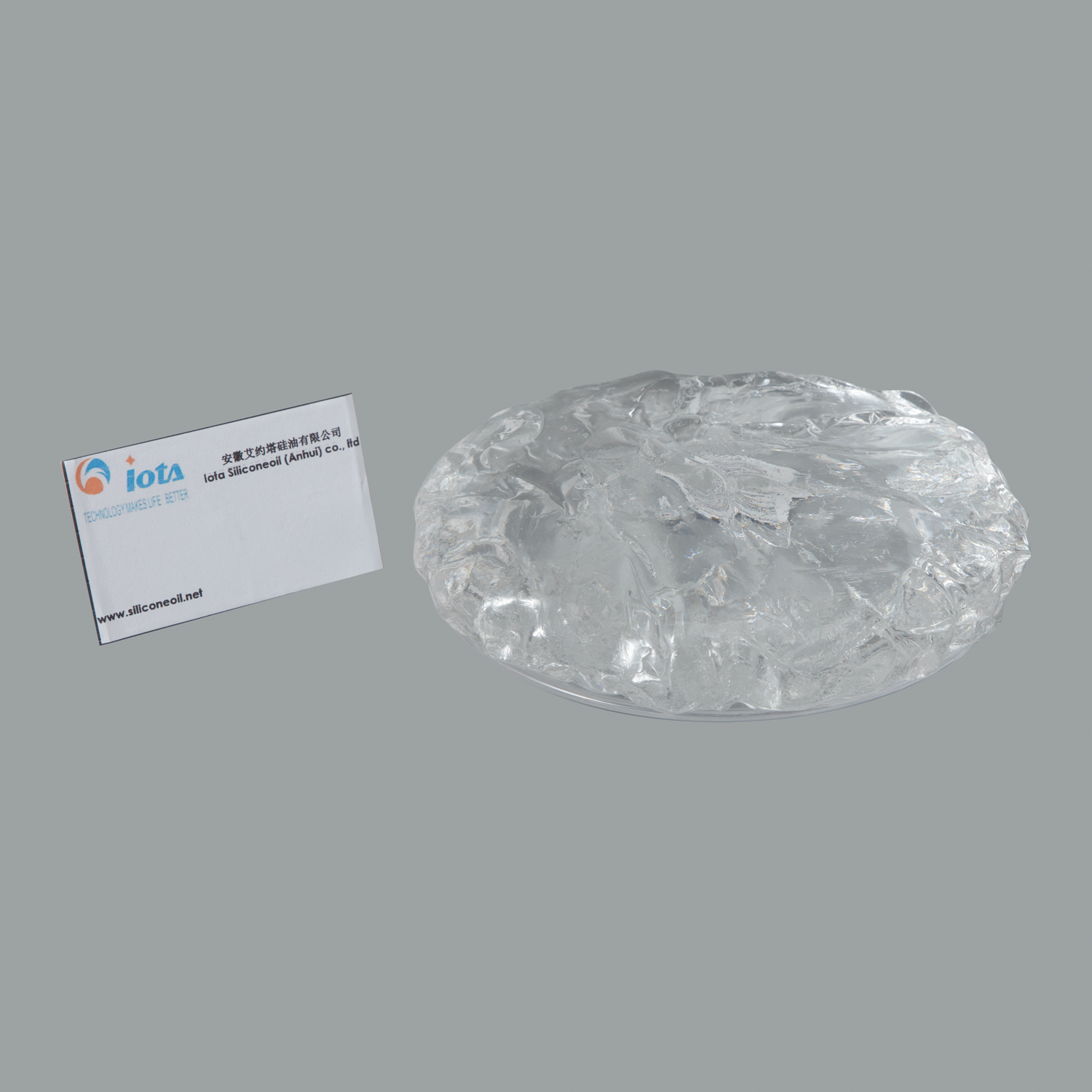

It also performs excellently in terms of processing convenience. After mixing the two components (A and B) in proportion, the material has a moderate viscosity, suitable for various processing methods such as doctor blading and dip coating. Manufacturers can easily produce dough mats of different sizes and thicknesses to meet the needs of different scenarios such as households and small workshops. The cured product is translucent, with a simple and clean appearance. Moreover, colors can be added to Component B as needed to produce dough mats of different colors, taking into account both practicality and aesthetics.

However, several details should be noted during use: it cures relying on a platinum catalyst, and Component A contains the catalyst, so catalyst poisoning should be avoided to prevent affecting the curing effect. It should be stored in an environment below 23°C, and can be stored for 12 months if unopened. After the expiration date, its performance must be tested and confirmed to be qualified before it can be used continuously.

This silicone rubber, with "durability" as its core advantage and also taking into account safety and appearance, turns dough mats from "consumables" into "durable goods" and provides more long-lasting companionship for everyone's home pasta making.