During the use and transportation of electronic products, static electricity is often an invisible "killer"—minor cases may cause equipment malfunctions, while severe ones can damage precision components. However, the emergence of an anti-static fumed silicone gel has brought a new solution for electronic product protection. With its excellent anti-static effect and comprehensive performance, it has become a "new tool" in the fields of electronic protective cases and rubber roller production.

The core advantage of this anti-static fumed silicone gel lies in its excellent anti-static effect. Its surface resistance can be stably controlled within a specific range, just like putting an "anti-static coat" on the product. It can effectively conduct static charges and prevent static accumulation. For example, when used to make protective cases for mobile phones and tablets, even with frequent use in dry environments, it can reduce the interference of static electricity on device screens and internal components; when used to make rubber rollers for electronic production lines, it can also prevent static electricity from attracting dust, ensuring that products remain clean during transportation and reducing production defect rates.

The odorless feature gives it an edge in the protection of close-contact electronic products. Many traditional anti-static materials have a pungent odor, which may affect the user experience with long-term use. However, this fumed silicone gel adopts an environmentally friendly formula, and the products made from it are odorless. Whether it is used to make protective cases for children's electronic toys or storage cases for daily-use headphones, it allows users to touch with confidence, balancing safety and comfort.

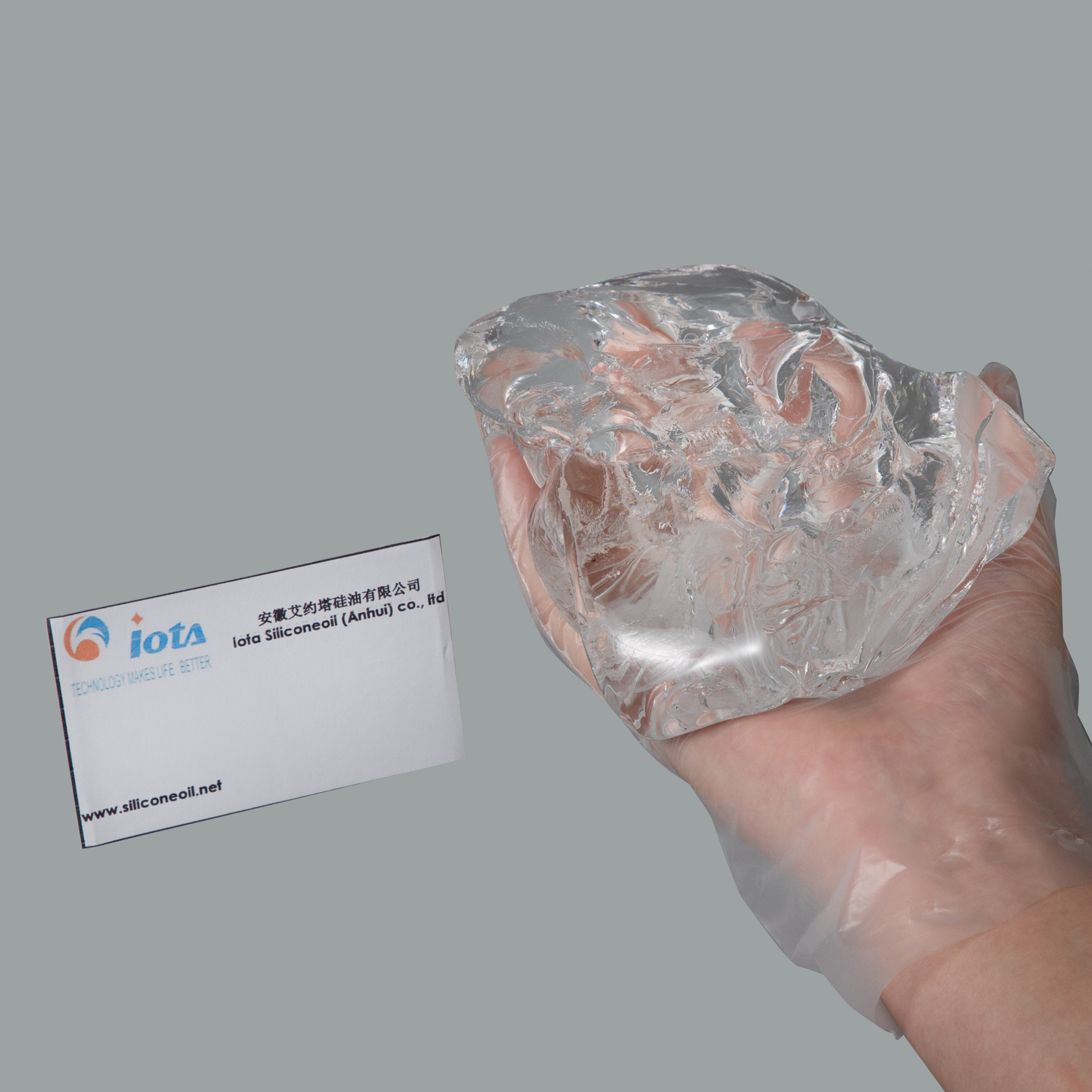

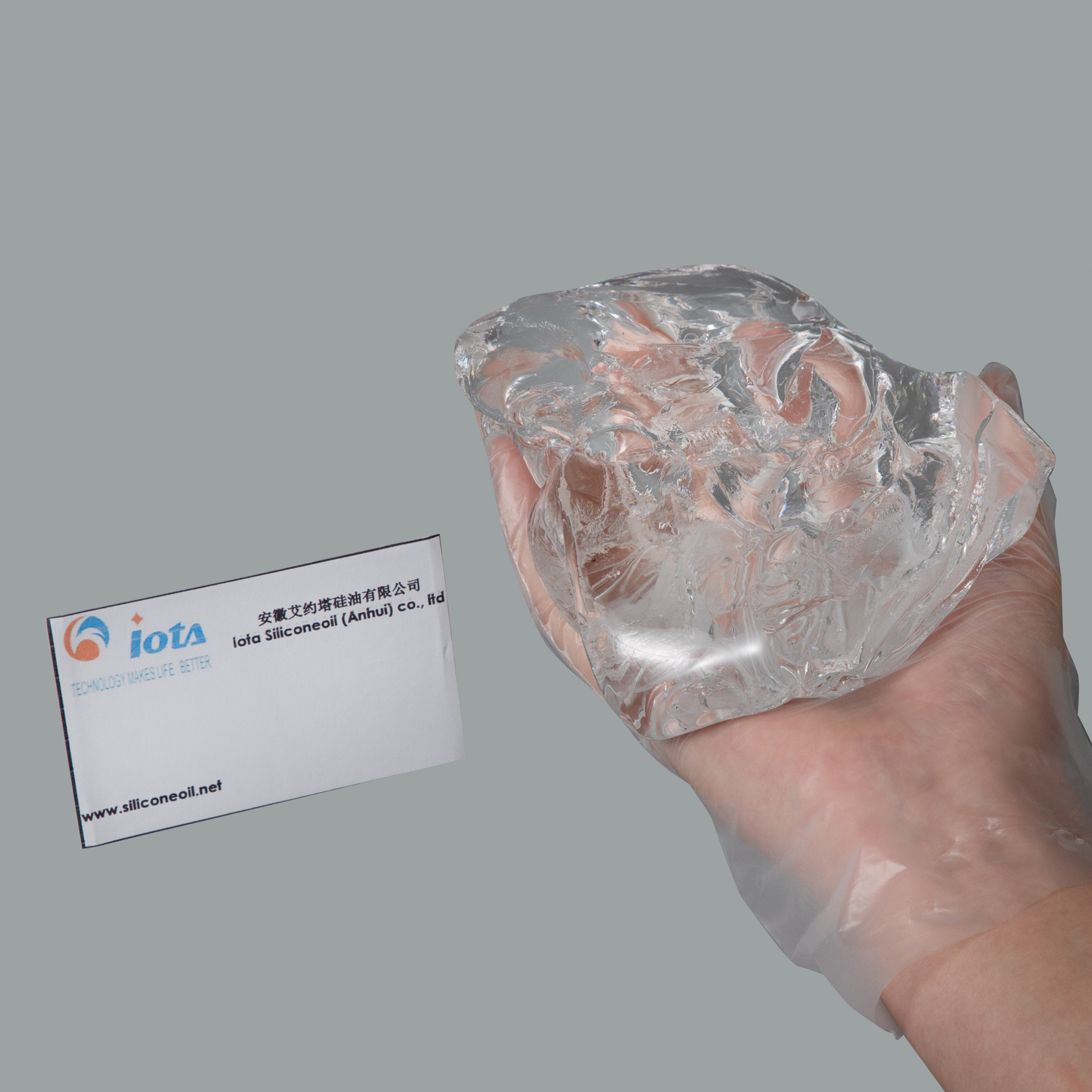

The high-strength performance ensures the durability of the products. Electronic product protective cases and rubber rollers inevitably encounter collisions and friction during use. This fumed silicone gel has a maximum tensile strength of 10.0MPa, like adding a "solid shield" to the product—it is not easy to break even when subjected to large external forces. Its maximum tear strength reaches 25KN/m, with excellent damage resistance, which can maintain the complete shape of the product for a long time. For instance, industrial rubber rollers used for transporting electronic components, when made from this gel, can withstand long-term high-intensity operation, reduce replacement frequency, and lower usage costs.

In terms of typical data, products of different grades (HTV-4930 to HTV-4970) can meet diverse needs: the hardness ranges from 30 Shore A to 70 Shore A, which can be selected according to the required hand feel of the product; HTV-4930 has an elongation of 900%, suitable for protective cases that require high elasticity; HTV-4950 has outstanding tensile strength and tear strength, suitable for rubber rollers that have high durability requirements. At the same time, it has passed the RoHS certification, ensuring material compliance and providing reliable support for enterprise production.