Recently, a two-component addition-cure liquid silicone rubber specially designed for baby products has quietly gained popularity. With its outstanding performance and safety advantages, it has become the material of choice for numerous baby product manufacturers, adding an extra "protective shield" to the safety of babies' daily supplies.

For parents, the safety of their babies' products is always a top priority, especially for items that babies frequently chew on, such as pacifiers and teething toys. The most prominent advantage of this high bite-resistant silicone rubber is its "bite resistance" – it can easily withstand the chewing needs of babies during the teething period, is not easy to break, and fundamentally reduces the safety risks caused by the falling off of small parts. Moreover, it is a food-grade material that fully complies with multiple international safety standards such as BfR, FDA, and ROHS. Parents do not need to worry about their babies coming into contact with harmful substances during use, allowing them to use the products with greater peace of mind.

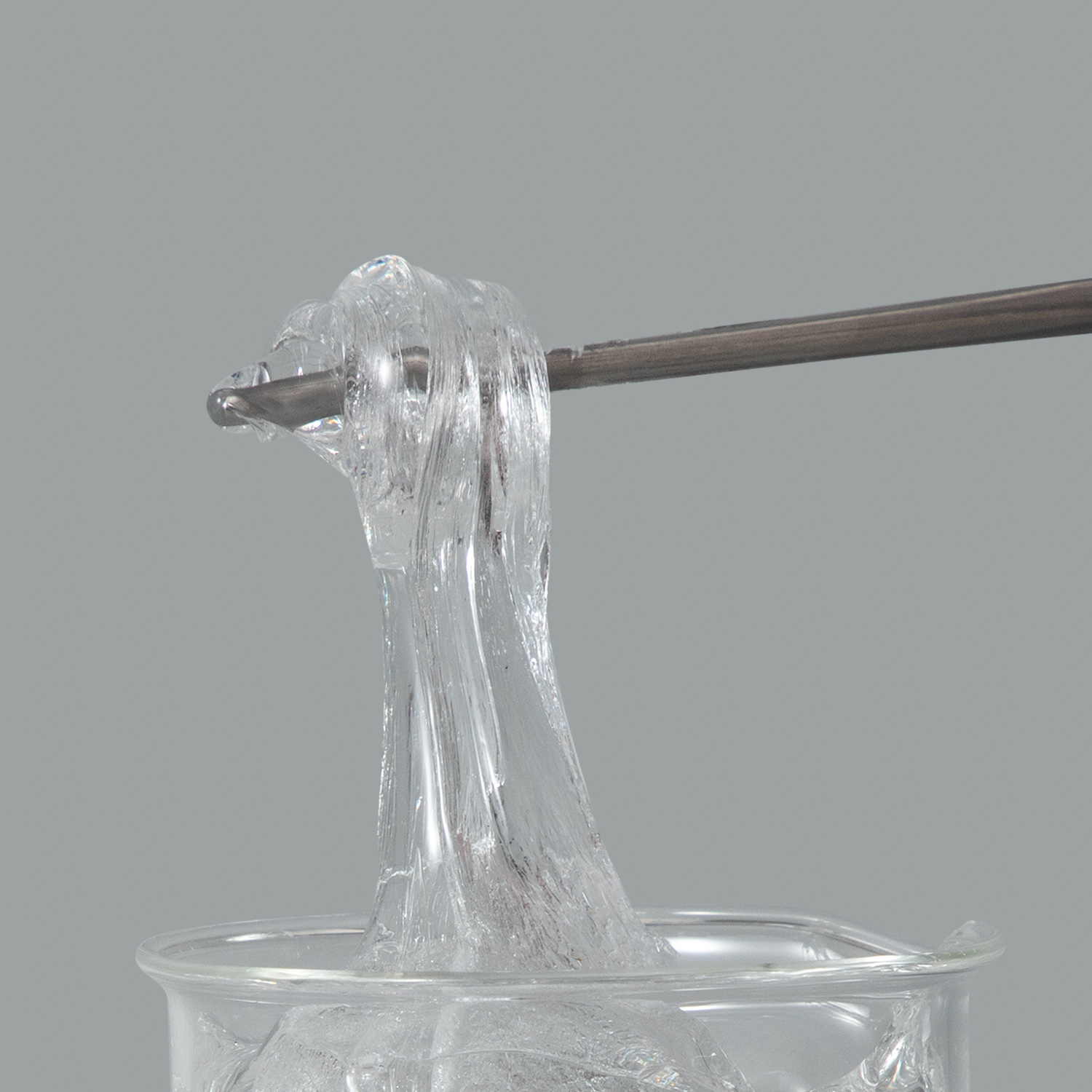

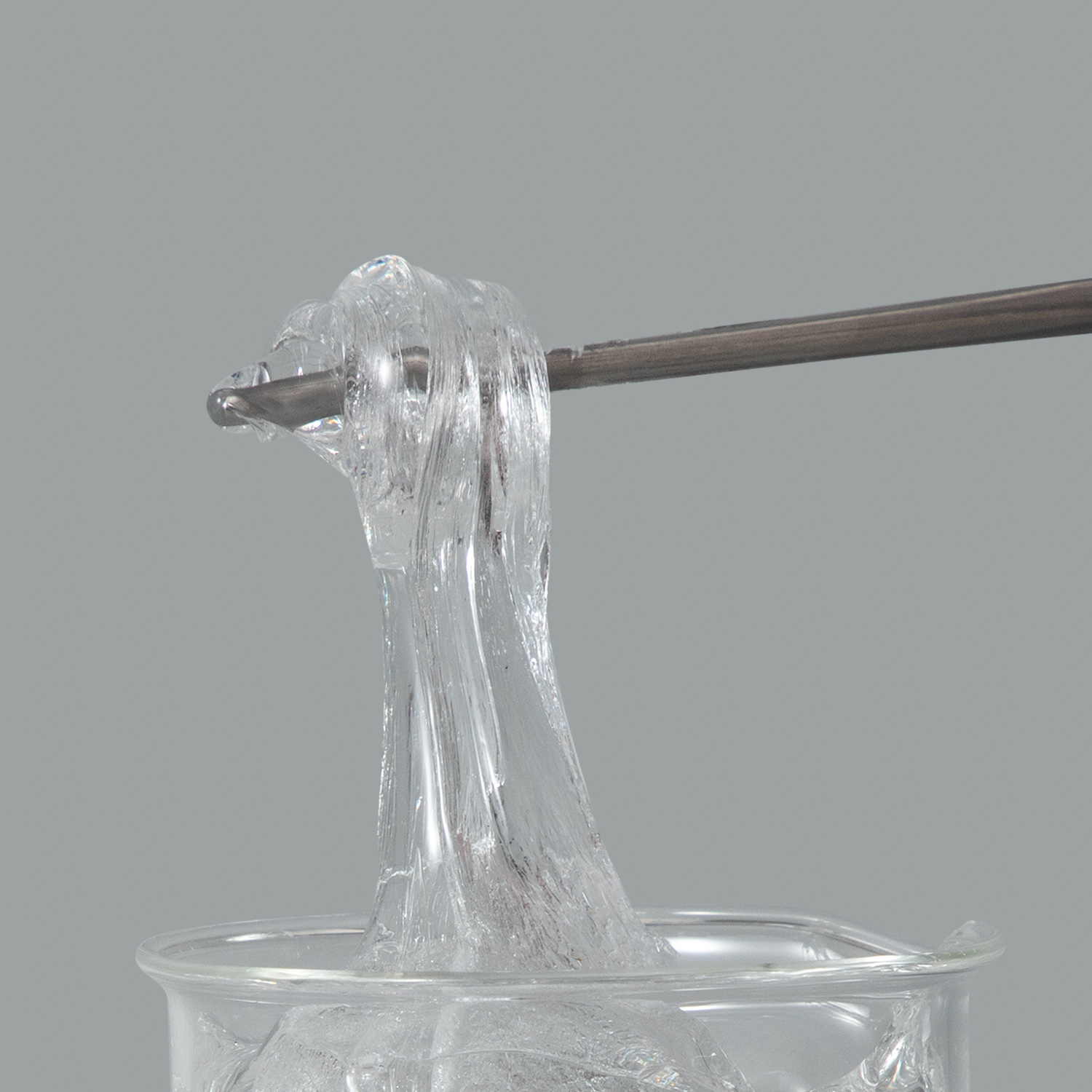

In terms of user experience, its performance is equally impressive. As a two-component material, it adopts a 1:1 mixing ratio, which is very convenient to operate and does not require complex proportioning processes, greatly reducing the operational difficulty in the production process. At the same time, it also has excellent demoldability. When producing various baby products, the finished products can be easily separated from the molds. This not only reduces losses during production but also ensures that the product surface is smooth and flat, enhancing the product texture.

In terms of production efficiency, this silicone rubber also provides strong support for manufacturers. It has the characteristic of rapid thermal curing and can complete curing efficiently at different temperatures: at 130°C, it only takes 90 seconds to cure and form; when the temperature is increased to 150°C, the curing time is even shortened to 45 seconds. This means that manufacturers can complete production in a shorter time, effectively improving production efficiency and shortening the product delivery cycle.

Currently, this high bite-resistant silicone rubber has been widely used in the production of various baby products. In addition to common pacifiers, it can also be used to make injection-molded products with complex structures such as teething toys and baby tableware accessories. It has injected new vitality into the baby product market and also brought safer and higher-quality choices for parents and babies.