In the baby products industry, material quality and production efficiency have always been the core concerns of manufacturers. Recently, a two-component, high-adhesion addition-cure liquid silicone rubber has won the favor of numerous baby product manufacturers with its dual advantages of "high quality + high efficiency", becoming a crucial force in driving the production upgrading of the industry.

From the perspective of production efficiency, this silicone rubber can be called a "speed booster". Its rapid thermal curing property breaks the bottleneck of slow curing of traditional materials: at 130°C, a 2mm-thick material can complete curing in just 90 seconds; if the temperature is increased to 150°C, the curing time is directly halved to only 45 seconds. For manufacturers engaged in large-scale production, this feature can significantly shorten the production cycle, enable the production of more products within the same time, greatly increase production capacity, and help enterprises better respond to fluctuations in market demand.

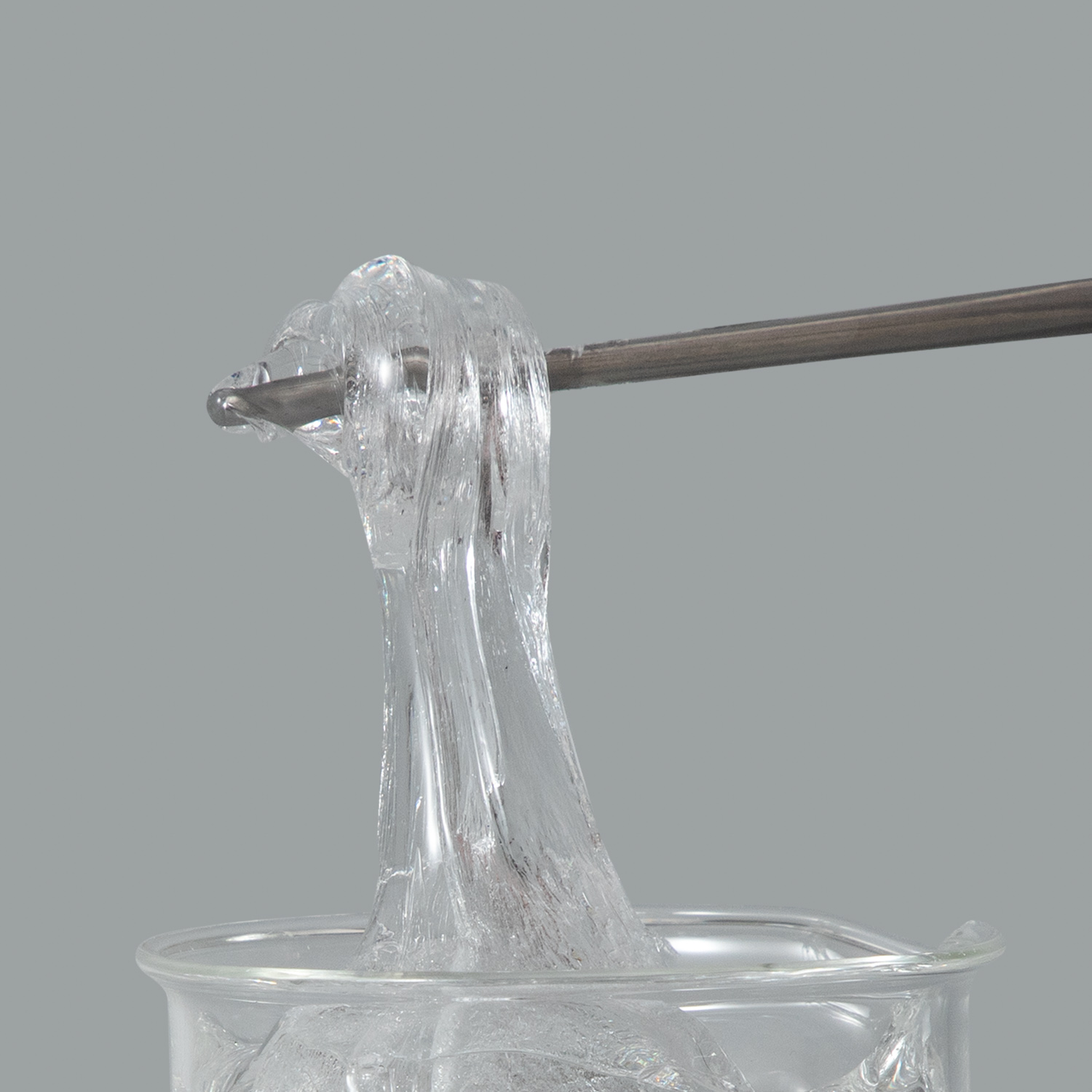

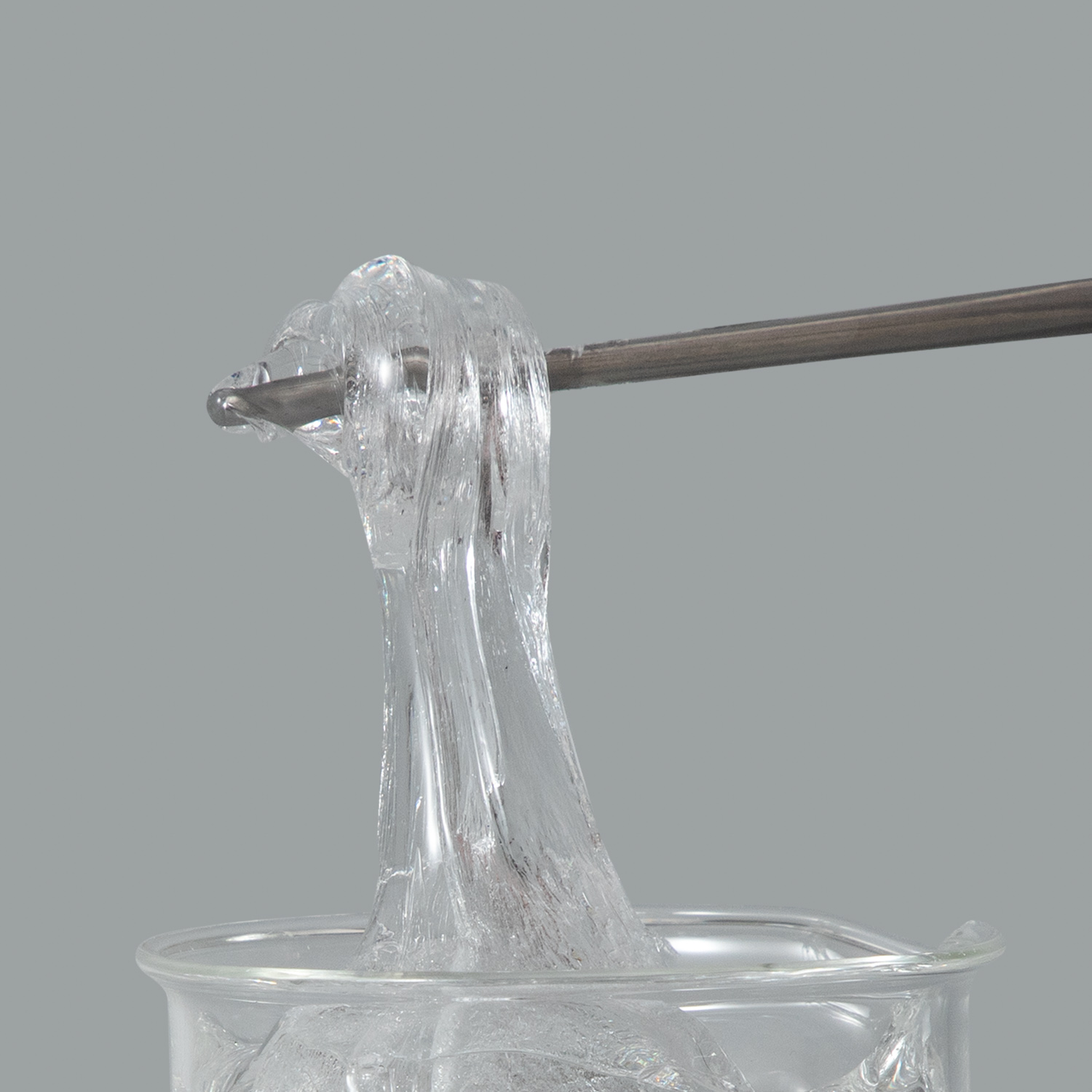

In terms of quality, it also stands the test. The cured product possesses excellent mechanical properties: the tensile strength can reach up to 10MPa, and the elongation rate ranges from 500% to 550%. This means that baby products made from it have high toughness and are not easy to deform—even if pulled by external force, they can quickly return to their original shape. Moreover, it has outstanding tear strength, with a maximum of 40KN/m. When facing frequent biting by babies during the teething period, it can effectively resist tearing, extend the service life of products, and reduce resource waste.

Furthermore, this silicone rubber has extremely strong adaptability in the production process. It is suitable for various injection molding processes, and can easily handle both simple small parts and baby products with complex structures, providing manufacturers with more room for product design. At the same time, its excellent demoldability ensures smoother demolding of finished products, avoiding product damage caused by difficult demolding, reducing production costs, and improving production efficiency.

As a food-grade material, it has also passed a number of international safety certifications, ensuring the safety of baby products from the source. It is believed that with the further promotion of this silicone rubber, it will help more baby product enterprises achieve dual improvements in efficiency and quality, and drive the industry towards a more efficient and safer direction.